Basic Information

| Place of Origin: | Qingdao China |

| Brand Name: | TSKY |

| Certification: | ISO, CE, BV, FDA,DIN |

| Model Number: | NN100 |

| Minimum Order Quantity: | 1 m |

| Price: | Negotiable |

| Packaging Details: | Paging Details --- Maximum 500m per roll for rubber EP conveyor belts --- Cassette package is available for abrasion resistant conveyor belts --- One 20" container can load 6--8 rolls DIN-Y conveyor belts --- One cka40" container can load 8--10 rolls stone |

| Delivery Time: | 5-8 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 50000 m/month |

Detail Information

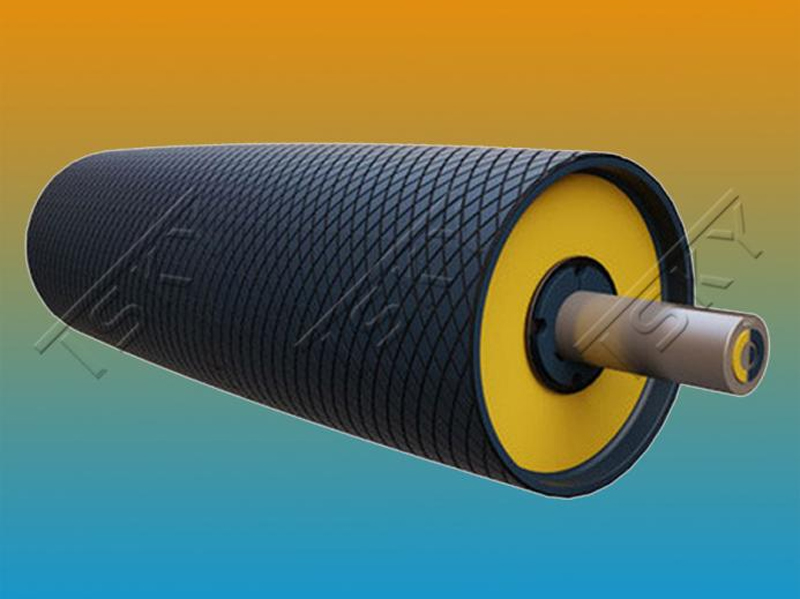

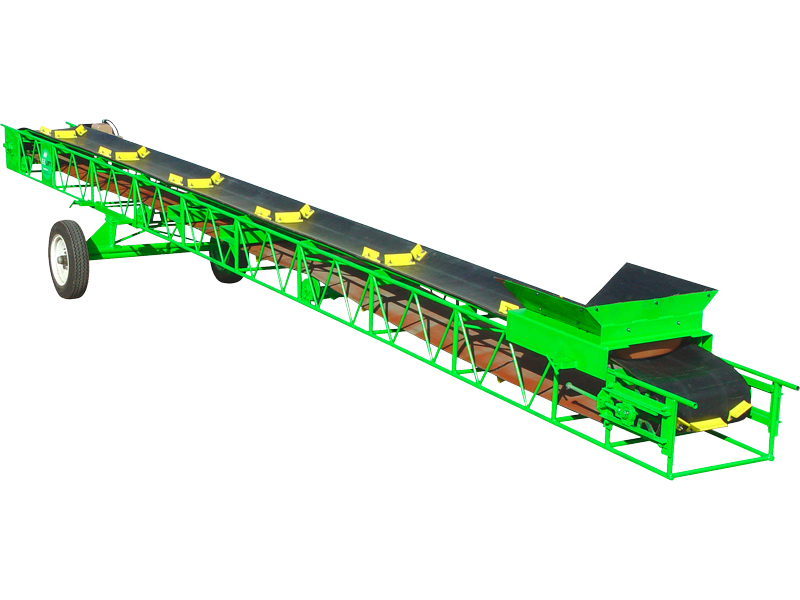

| Name: | NN100 Nylon Rubber Belt Ware-Resistant For Mining Coal Stone Bulk Material | Material: | Cotton (CC), Cover Rubber, Nylon(NN), Polyester (EP) |

| Application: | Cement, Mine, Coal Mining, Quarry, Industry | Structure: | Belt Conveyor, EP/NN Fabric Conveyor Rubber Belt |

| Standard: | DIN, JIS, ISO, CEMA, GB | Color: | Black |

| Belt Width: | 300-2200 Mm | Condition: | New |

| Wanranty: | 12 Months | ||

| High Light: | NN100 nylon rubber conveyor belt, CEMA Nylon Rubber Conveyor Belt, NN100 Conveyor Rubber Belt | ||

Product Description

NN100 Nylon Rubber Belt Ware-Resistant For Mining Coal Stone Bulk Material Transportation Fabric conveyor belts or textile conveyor belts, are used principally for heavy-duty, abrasive materials,to transport all types of bulk material, including mining, stone and earth handling, building industries, recycling, steel processing, wood, paper and pulp. They are a more cost-effective option for shorter conveying distances and lower capacities than steel cord belts. TSKY’s fabric conveyor belts are known as TSKY Textile belts. Applicable Use of NN100 Nylon Rubber Belt Ware-Resistant For Mining Coal Stone Bulk Material Transportation Fabric conveyor belts or textile conveyor belts, are used principally for heavy-duty, abrasive materials,to transport all types of bulk material, including mining, stone and earth handling, building industries, recycling, steel processing, wood, paper and pulp. It is mainly used to transport powder, small and medium granular or less wearing material and some other articles to the belt at common temperature. Grade standards: It carries out standard of GB/T7984-2013 “General-used Conveyor Belts”, DIN22103

Applicable Use of NN100 Nylon Rubber Belt Ware-Resistant For Mining Coal Stone Bulk Material Transportation Fabric conveyor belts or textile conveyor belts, are used principally for heavy-duty, abrasive materials,to transport all types of bulk material, including mining, stone and earth handling, building industries, recycling, steel processing, wood, paper and pulp. It is mainly used to transport powder, small and medium granular or less wearing material and some other articles to the belt at common temperature. Grade standards: It carries out standard of GB/T7984-2013 “General-used Conveyor Belts”, DIN22103 | Grade standards and characteristics | |||

| GRADE | ISO | DIN | Characteristics |

| X | H | X | Wear-resistant, heavy-duty cover for sharp and lumpy material, or extreme drop heights |

| Y | L | Y | Wear-resistant cover for standard applications |

| AA, W | D | W | Wear-resistant cover, for fine and abrasive material |

| UAR, UAR30 | D | Y, W | Extremely wear-resistant cover, for fine and abrasive materia |

Features of TSKY Rubber Conveyor Belt : The belt's wear-resistant properties make it ideal for abrasive materials, ensuring that it lasts for a long time.This conveyor belt has excellent resistance to impact, tears, and punctures, making it well-suited for use in harsh environments. Furthermore, its oil-resistant properties make it an ideal choice for industries such as mining, construction, and agriculture.The Bulk Material NN150 Wear Resistant Conveyor Belt is easy to install, maintain, and has low stretching characteristics that minimize maintenance costs. The belt's superior design results in a smooth and efficient operation, reducing downtime and improving productivity.Overall, the Bulk Material NN150 Wear Resistant Conveyor Belt is a reliable and high-performing product for the transportation of heavy and abrasive materials. Its superior design and durable construction make it an ideal choice for industries looking to enhance their operational efficiency while reducing maintenance costs. Our Conveyor Rubber Belts are designed with various layers of synthetic fabrics that are treated for low elongation (1 to 3.5%) and excellent adhesion to rubber. Our belts have lengthwise polyester threads and crosswise polyamide threads that result in a high tensile strength-to-weight ratio, superior flexibility, and remarkable resistance to impact and chemicals. We also offer customization options for thread materials and weaves.Our Cover Grades come in various options and are made of top-quality rubber with exceptional resistance to abrasion, shearing, and impact as well as excellent ageing properties. The appropriate cover grade for your needs depends on the specific application, and it is essential to consider the application carefully to determine the working life of the belt.Our Conveyor Rubber Belts offer several resistances such as Wear-resistant, Heat-resistant, Flame-resistant, Tear-Resistant, Cold-Resistant, Oil-Resistant, Acid And Alkali Resistant, etc. The Wear-resistant belts in grades X, Y, and W are ideal for conveying bulky, sharp materials like heavy, abrasive rocks, thanks to their exceptional capability of handling abrasion, wear, impact, and other heavy-duty loads. The belts with several heat-resistant grades(T120 and T200) are perfect for high-temperature applications, with continuous transport temperatures of up to 190 °C and peaks of up to 200 °C. Our Flame-resistant belts meet the safety specifications of EN12882 for above-ground operations and EN14973 for underground use. The Tear-resistant layers include high-strength steel mesh, nylon net, aramid fiber net, and low-extensity zinc (copper) plating steel cord, and they have additional transverse reinforcement layers to prevent tearing during harsh conditions. Our Oil-resistant belts are designed for transporting and sucking oil supplies in different job environments, except for solvent oils. Lastly, our Acid and Alkaline Resistant belts are blended with rubber and plastic and filled with inert materials that offer excellent resistance, handling harsh working environments like phosphate fertilizer manufacturing and sea salt drying, and are made into rings using cotton or nylon canvas or EP canvas as the strong layer.

Features of TSKY Rubber Conveyor Belt : The belt's wear-resistant properties make it ideal for abrasive materials, ensuring that it lasts for a long time.This conveyor belt has excellent resistance to impact, tears, and punctures, making it well-suited for use in harsh environments. Furthermore, its oil-resistant properties make it an ideal choice for industries such as mining, construction, and agriculture.The Bulk Material NN150 Wear Resistant Conveyor Belt is easy to install, maintain, and has low stretching characteristics that minimize maintenance costs. The belt's superior design results in a smooth and efficient operation, reducing downtime and improving productivity.Overall, the Bulk Material NN150 Wear Resistant Conveyor Belt is a reliable and high-performing product for the transportation of heavy and abrasive materials. Its superior design and durable construction make it an ideal choice for industries looking to enhance their operational efficiency while reducing maintenance costs. Our Conveyor Rubber Belts are designed with various layers of synthetic fabrics that are treated for low elongation (1 to 3.5%) and excellent adhesion to rubber. Our belts have lengthwise polyester threads and crosswise polyamide threads that result in a high tensile strength-to-weight ratio, superior flexibility, and remarkable resistance to impact and chemicals. We also offer customization options for thread materials and weaves.Our Cover Grades come in various options and are made of top-quality rubber with exceptional resistance to abrasion, shearing, and impact as well as excellent ageing properties. The appropriate cover grade for your needs depends on the specific application, and it is essential to consider the application carefully to determine the working life of the belt.Our Conveyor Rubber Belts offer several resistances such as Wear-resistant, Heat-resistant, Flame-resistant, Tear-Resistant, Cold-Resistant, Oil-Resistant, Acid And Alkali Resistant, etc. The Wear-resistant belts in grades X, Y, and W are ideal for conveying bulky, sharp materials like heavy, abrasive rocks, thanks to their exceptional capability of handling abrasion, wear, impact, and other heavy-duty loads. The belts with several heat-resistant grades(T120 and T200) are perfect for high-temperature applications, with continuous transport temperatures of up to 190 °C and peaks of up to 200 °C. Our Flame-resistant belts meet the safety specifications of EN12882 for above-ground operations and EN14973 for underground use. The Tear-resistant layers include high-strength steel mesh, nylon net, aramid fiber net, and low-extensity zinc (copper) plating steel cord, and they have additional transverse reinforcement layers to prevent tearing during harsh conditions. Our Oil-resistant belts are designed for transporting and sucking oil supplies in different job environments, except for solvent oils. Lastly, our Acid and Alkaline Resistant belts are blended with rubber and plastic and filled with inert materials that offer excellent resistance, handling harsh working environments like phosphate fertilizer manufacturing and sea salt drying, and are made into rings using cotton or nylon canvas or EP canvas as the strong layer.