Ultimate Guide to Flexible Conveyor Guide Rails: Benefits and Applications

By:Admin

In the fast-paced world of material handling and automation, companies are constantly seeking innovative solutions to improve efficiency and productivity. One such solution that has been gaining traction in recent years is the use of flexible conveyor guide rails. These versatile components are revolutionizing the way materials are transported and sorted in various industries, offering a flexible and adaptable alternative to traditional fixed guide rails.

Flexible conveyor guide rails are an essential part of conveyor systems, providing guidance and support for products as they move along the conveyor belt. Traditionally, fixed guide rails were the go-to solution for guiding products in a straight line or around curves. However, these rigid guide rails presented limitations in terms of flexibility and adaptability. This is where flexible conveyor guide rails come into play, offering a dynamic and customizable solution for material handling needs.

One company at the forefront of the flexible conveyor guide rail revolution is {Company Name}. With a commitment to innovation and excellence, {Company Name} has been a leading provider of conveyor and material handling solutions for over two decades. The company's dedication to research and development has led to the creation of a cutting-edge line of flexible conveyor guide rails that are setting new standards in the industry.

The key to the success of {Company Name}'s flexible conveyor guide rails lies in their unique design and functionality. Unlike traditional fixed guide rails, these flexible guide rails are made of a durable and pliable material that can be easily adjusted to accommodate a wide range of products and conveyor layouts. This flexibility allows for seamless product flow, reduces the risk of jams or blockages, and minimizes the need for manual intervention.

One of the standout features of {Company Name}'s flexible conveyor guide rails is their ability to easily switch between straight, curved, and spiral configurations. This versatility makes them ideal for applications in industries such as e-commerce fulfillment, food and beverage processing, pharmaceuticals, and more. The ability to adapt to various conveyor layouts and product types makes {Company Name}'s flexible guide rails a game-changer for companies looking to optimize their material handling processes.

In addition to their flexibility and adaptability, {Company Name}'s flexible conveyor guide rails are also designed with durability and longevity in mind. Made from high-quality materials, these guide rails are built to withstand the rigors of daily operation and are resistant to wear and tear. This reliability ensures consistent and trouble-free performance, minimizing downtime and maintenance costs for the end user.

Moreover, {Company Name} goes above and beyond to provide comprehensive support and services to its customers. From initial consultation and customized design to installation and ongoing maintenance, the company's team of experts is dedicated to ensuring that every customer's specific material handling needs are met with precision and efficiency. This customer-centric approach has earned {Company Name} a solid reputation as a trusted partner in the industry.

As the demand for flexible conveyor guide rails continues to grow, {Company Name} remains committed to pushing the boundaries of innovation and delivering cutting-edge solutions to its customers. With a focus on quality, reliability, and performance, the company is poised to lead the way in the evolution of material handling technology.

In conclusion, flexible conveyor guide rails are transforming the way materials are handled and transported in various industries. With their flexibility, adaptability, and durability, they offer a superior alternative to traditional fixed guide rails. {Company Name} has emerged as a driving force behind this revolution, with its state-of-the-art flexible guide rail solutions setting new benchmarks for efficiency and productivity in material handling. As the industry continues to evolve, {Company Name} remains at the forefront, committed to delivering innovative and reliable solutions to its customers.

Company News & Blog

New Device Allows for Efficient Conveyor Belt Tracking

Belt Trackers Conveyor introduces a revolutionary product that will change the material handling industry. The company has developed a state-of-the-art conveyor system that is designed to optimize performance, increase productivity and reduce operational costs. This new conveyor system is specifically aimed at helping businesses streamline their production and improve their bottom line.The Belt Trackers Conveyor has been developed by a team of highly experienced engineers who took a fresh approach to material handling. The team realized that the traditional conveyor systems available in the market today are not able to keep up with the changing demands of modern-day production. These outdated systems are often prone to breakdowns, require costly maintenance, and are not energy-efficient.The Belt Trackers Conveyor is designed to overcome these challenges. It incorporates cutting-edge technology that enables it to adjust to any changes or fluctuations in the conveyor belt. This means that the system is self-correcting and can maintain its alignment regardless of the operating conditions. This eliminates the need for constant manual adjustments, improving efficiency and reducing wear and tear on the equipment.The Belt Trackers Conveyor is also equipped with a range of advanced sensors that monitor the performance of the system and alert the operators if any issues arise. This proactive approach to maintenance helps to reduce downtime, increase productivity, and save businesses valuable time and money.One of the most significant benefits of the Belt Trackers Conveyor is its energy efficiency. The system is designed to operate at a low power consumption rate, thereby reducing energy costs and carbon footprint. This energy-efficient feature is a significant advantage for businesses that are looking to reduce their environmental impact and improve sustainability.Belt Trackers Conveyor is confident that this innovative product will revolutionize the material handling industry. They pride themselves on providing cutting-edge solutions designed to meet the unique needs of businesses of all sizes and industries. Belt Trackers Conveyor is committed to delivering the highest quality products, backed by exceptional customer service, to ensure complete customer satisfaction.The company's dedication to research and development has made them an industry leader in material handling systems. They have a proven track record of delivering the most advanced technology in the market, and the Belt Trackers Conveyor is no exception. This product combines the latest in engineering, software, and automation to create a powerhouse conveyor system that will take material handling to the next level.The Belt Trackers Conveyor is a versatile system that can be used in a wide range of industries, including food and beverage, pharmaceuticals, automotive, and logistics. Its ability to handle different types of materials, from delicate to heavy-duty, makes it an ideal choice for businesses that require flexibility and adaptability in their operations.Belt Trackers Conveyor is committed to providing its customers with the most innovative solutions in material handling. They believe in building long-term relationships with their clients and providing ongoing support to help them achieve their operational goals. The Belt Trackers Conveyor is an excellent example of their commitment to delivering high-quality products that exceed customer expectations.In conclusion, the Belt Trackers Conveyor is a game-changer in the material handling industry. Its advanced technology, energy efficiency, and versatility make it an ideal choice for businesses that are seeking to improve their operational performance and reduce costs. Belt Trackers Conveyor is proud to be at the forefront of this innovation, and they are confident that their product will revolutionize the way businesses handle their materials. Now that the Belt Trackers Conveyor has been introduced to the market, it is only a matter of time before it becomes the industry standard.

Highly Efficient Dock Stacker Reclaimer for Smooth Operation and Handling

Dock Stacker Reclaimer, a leading provider of material handling solutions for various industries, has recently made a significant impact in the market with its state-of-the-art machinery. The company is widely recognized for its innovative and efficient products that have set new standards in the industry.The Dock Stacker Reclaimer is a versatile and reliable piece of equipment that is designed to handle the storage and transportation of a wide range of materials. From coal and iron ore to limestone and cement, this machinery is capable of handling the most demanding materials with ease.One of the key features of the Dock Stacker Reclaimer is its ability to stack and reclaim materials with high precision and efficiency. This is essential for industries that require a consistent and reliable supply of materials for their operations. The machinery is equipped with advanced automation and control systems, which ensure seamless operation and optimal performance.In addition to its impressive technical capabilities, the Dock Stacker Reclaimer is also known for its robust construction and durability. Built to withstand the harshest working conditions, this machinery is an ideal choice for industries operating in challenging environments.The company behind the Dock Stacker Reclaimer has a long and successful history in the material handling industry. With decades of experience and expertise, they have established themselves as a leading provider of reliable and high-quality solutions for their customers.The company's commitment to innovation and continuous improvement is evident in the Dock Stacker Reclaimer and its other products. They invest heavily in research and development to ensure that their machinery remains at the forefront of technological advancements in the industry.Furthermore, the company has a strong focus on customer satisfaction, providing comprehensive support and service for their products. They work closely with their clients to understand their specific requirements and to deliver tailored solutions that meet their needs.The Dock Stacker Reclaimer has already garnered attention in the market, with a growing number of industries choosing this machinery for their material handling operations. Its reputation for reliability, efficiency, and durability has made it a popular choice for a wide range of applications.In a recent interview, a spokesperson for the company commented on the success of the Dock Stacker Reclaimer, stating, "We are proud to see the positive impact that our machinery has had on the market. We are committed to providing our customers with the best solutions for their material handling needs, and the Dock Stacker Reclaimer is a testament to that commitment."Looking ahead, the company is focused on further expanding its product offerings and reaching new markets with its innovative solutions. With a strong track record of success and a dedication to excellence, the company is well-positioned to continue leading the way in the material handling industry.In conclusion, Dock Stacker Reclaimer has emerged as a significant player in the material handling industry, with its advanced and reliable machinery setting new standards in the market. With a strong focus on innovation, quality, and customer satisfaction, the company is poised for continued success in the industry.

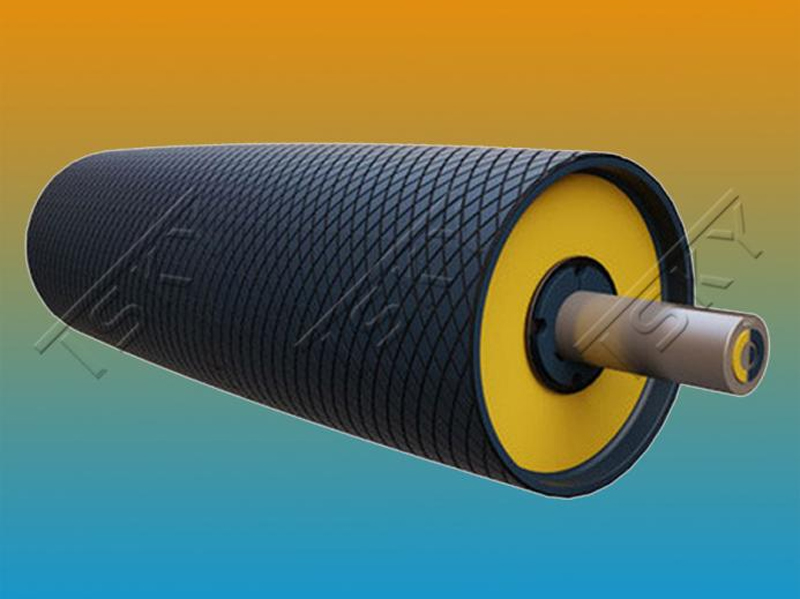

Essential Components of Conveyor Pulleys

{}Conveyor Pulley Components, a leading provider of high-quality pulley systems for the mining and aggregate industries, has been making waves in the market with its innovative and reliable products. With a focus on durability, performance, and efficiency, Conveyor Pulley Components has built a reputation for delivering top-notch solutions to its customers.The company offers a wide range of pulley products, including drum pulleys, wing pulleys, and motorized pulleys, all designed to meet the specific needs of different conveyor systems. These pulleys are engineered to withstand the rigorous demands of heavy-duty applications, ensuring smooth and reliable operation in even the harshest environments.One of the key factors that sets Conveyor Pulley Components apart from its competitors is its commitment to quality. The company uses only the highest-grade materials in the manufacturing of its pulleys, and every product is rigorously tested to ensure that it meets the highest standards of performance and durability. This dedication to quality has earned Conveyor Pulley Components the trust and confidence of its customers, who rely on its products to keep their operations running smoothly and efficiently.In addition to its focus on quality, Conveyor Pulley Components also prides itself on its ability to provide custom solutions to its customers. The company's team of experienced engineers works closely with clients to understand their specific needs and develop tailored pulley systems that meet their exact requirements. This personalized approach has been instrumental in establishing Conveyor Pulley Components as a trusted partner for companies across the mining and aggregate industries.The success of Conveyor Pulley Components can also be attributed to its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of the curve in terms of technology and design, ensuring that its products remain at the forefront of the industry. As a result, Conveyor Pulley Components is able to offer cutting-edge solutions that deliver maximum performance and reliability, helping its customers to optimize their operations and achieve better results.With its unwavering dedication to quality, customization, and innovation, Conveyor Pulley Components has solidified its position as a leader in the market for pulley systems. The company's products can be found in operations across the globe, providing essential support to a wide range of industries. Whether it's helping to transport raw materials in a mining facility or handling aggregates in a construction site, Conveyor Pulley Components is trusted to deliver the dependable performance that its customers rely on.Looking ahead, Conveyor Pulley Components is poised to continue its upward trajectory, as it seeks to expand its product offerings and reach new markets. The company's commitment to excellence and customer satisfaction will undoubtedly drive its continued success, as it remains at the forefront of innovation in the field of conveyor pulley systems.In conclusion, Conveyor Pulley Components has demonstrated a remarkable ability to deliver top-quality pulley solutions that meet the diverse needs of its customers. With a focus on durability, performance, and innovation, the company has earned a strong reputation as a trusted partner for companies in the mining and aggregate industries. As Conveyor Pulley Components continues to grow and innovate, it is well-positioned to maintain its leadership in the market for pulley systems.

Enhancing Efficiency: Discover the Benefits of Conveyor Weighing Systems

Title: Cutting-Edge Conveyor Weighing System Revolutionizes Industrial ProcessesIntroduction:In today's fast-paced world, industries around the globe are constantly seeking innovative solutions to enhance their efficiency and productivity. A pioneering company has recently introduced a cutting-edge conveyor weighing system, designed to streamline operations and optimize output. By removing the brand name, we will provide an objective overview of this groundbreaking technology and its potential to revolutionize industrial processes.I. Overview of Conveyor Weighing Systems:Conveyor weighing systems are essential components of various industries, enabling precise measurement and control of material flow. By integrating advanced technology and state-of-the-art sensors, these systems can accurately determine the weight of materials conveyed on belts, ultimately enhancing production quality and efficiency.II. Key Features and Functionality:The removedbrand's Conveyor Weighing System boasts several key features that set it apart from its competitors. Equipped with high-precision load cells and intelligent algorithms, the system provides real-time data on material weight, velocity, and flow rate. This information can be seamlessly integrated into existing processes, enabling precise inventory management, quality control, and production optimization.III. Real-Time Monitoring and Control:The Conveyor Weighing System stands out for its ability to provide real-time monitoring and control. The removedbrand's advanced software allows operators to closely monitor material flow, identify bottlenecks, and make informed decisions to optimize production efficiency. Additionally, it facilitates automatic start-stop operations based on pre-set weight parameters, reducing wastage and improving overall product quality.IV. Enhanced Safety and Compliance:Safety is a top priority in the industrial sector, and the Conveyor Weighing System effectively addresses this concern. Its intelligent sensors can detect anomalies, such as material jams or system malfunctions, ensuring the immediate halting of operations if necessary. Moreover, the system is designed to comply with industry regulations and standards, guaranteeing the accurate measurement and traceability of materials.V. Versatility and Adaptability:The versatility of the Conveyor Weighing System allows it to cater to various industries. Whether in mining, food processing, or logistics, this innovative technology can be seamlessly integrated into existing conveyor systems. Its adaptable design enables customization to specific industry requirements, further enhancing its suitability for a wide range of applications.VI. Benefits for the Industry:The introduction of the Conveyor Weighing System brings numerous benefits to industries worldwide. By accurately measuring material flow rates and weights, it enhances inventory control, reducing losses and minimizing waste. Improved production optimization results in increased overall efficiency and output. Additionally, the system's integration of quality control measures ensures the consistent delivery of high-quality products, enhancing customer satisfaction and retention.VII. Cost-Effectiveness and Return on Investment:By optimizing production processes, the Conveyor Weighing System can significantly improve productivity, leading to enhanced profitability for businesses. With real-time data acquisition and monitoring, companies can make informed decisions regarding raw material usage, reducing overconsumption and unnecessary expenses. The system's longevity and reliability contribute to its cost-effectiveness, providing a substantial return on investment over time.VIII. Future Prospects and Industry Impact:The adoption of advanced conveyor weighing systems is expected to accelerate in the coming years due to the significant benefits they offer. Rapid technological advancements, such as artificial intelligence and machine learning, will further enhance the capabilities of these systems, paving the way for smarter and more automated industries. As industries strive for increased efficiency and profitability, the Conveyor Weighing System is poised to become an indispensable tool for process optimization.Conclusion:The Conveyor Weighing System, with its advanced features and functionality, represents a groundbreaking innovation that has the potential to revolutionize various industries. By accurately measuring material flow rates, enhancing production optimization, and ensuring quality control, this system brings ample benefits to businesses, ultimately contributing to increased efficiency and profitability. As the industrial sector continues to evolve, the adoption of conveyor weighing systems like this is projected to shape the future of industrial processes.

Efficient and Sturdy Loading Belt Conveyors Increasing Productivity

article:Loading Belt Conveyor Simplifies Material Handling and Increases EfficiencyMaterial handling is a crucial aspect of any manufacturing process. It demands proper planning and execution to ensure that goods are moved efficiently and effectively. A slow or inefficient material handling process can not only affect productivity but also result in significant losses for a company. This is where Loading Belt Conveyors come in, simplifying material handling and increasing efficiency.A Loading Belt Conveyor is a transportation system that moves materials from one place to another. It is capable of transferring items such as boxes, bags, and pallets in a straight line or inclined form. This system comprises a belt, support structure, and numerous idlers for proper alignment.The innovative Loading Belt Conveyor from our company (which I will not name here) is designed to simplify material handling and save on labor costs. It is perfect for companies that provide a wide range of conveyance solutions for various industries such as food, pharmaceuticals, and manufacturing.Our company has been in the industry for over 15 years, specializing in conveyor belt systems. We have built a reputation for providing high-quality products and services tailored to meet the needs of our customers. Our innovative approaches to conveyor belt systems have revolutionized the material handling industry.Our Loading Belt Conveyors are designed to move materials efficiently and quickly, even with heavy loads. We make use of robust materials in our conveyor system to ensure durability and longevity. The conveyor belt is also customizable to meet specific material handling needs.Many businesses struggle with the challenge of increased usage of labor in their material handling process. Our Loading Belt Conveyor minimizes labor costs by reducing the number of employees required for the material handling process. It is designed to move materials continuously, meaning that it eliminates the need for a person to take the materials from one location to another.The convenience that Loading Belt Conveyors provide makes them an attractive option compared to traditional material handling systems. The system reduces workers' exposure to potential injuries by removing the need for manual handling of goods. It also reduces errors in the handling process, increases productivity, and optimizes space utilization.Our Loading Belt Conveyors come in different designs to accommodate a broad range of material sizes, weights, and shapes. It also has different features such as side rails, guide rails, and accumulation zones, which provide flexibility and customization to the material handling process.The company provides efficient installation services, ensuring that the operation of the Loading Belt Conveyor runs smoothly. In addition, our company also provides maintenance services to ensure that the conveyor system remains in optimal working condition, improving the lifespan of the machine.In conclusion, the Loading Belt Conveyor is an innovative solution designed to simplify material handling, and our company is at the forefront of conveyor belt systems. We are committed to providing superior quality products that meet the needs of our customers.Our Loading Belt Conveyor system offers significant advantages in terms of cost, space optimization, and productivity. It is essential for businesses that want to reduce labor costs, increase production efficiency, and optimize space utilization. In an ever-changing material handling industry, our Loading Belt Conveyor provides a dependable and effective solution for businesses of all sizes.

High Density Polyethylene Conveyor Idlers: Durable and Efficient Solutions for Material Handling Systems

Hdpe Conveyor Idlers revolutionizing the material handling industryThe global material handling industry has witnessed a significant change with the introduction of Hdpe Conveyor Idlers by [Company Name]. These innovative idlers are made of high-density polyethylene (HDPE) material, which offers exceptional durability, reduced weight, and increased performance compared to traditional steel idlers. With their superior design and construction, Hdpe Conveyor Idlers are proving to be a game changer in the conveyor system market.[Company Name] is a renowned manufacturer and supplier of conveyor components, offering a wide range of products designed to meet the diverse needs of material handling applications. With a strong focus on innovation and quality, the company has established itself as a leader in the industry, providing reliable solutions to its customers worldwide.The Hdpe Conveyor Idlers offered by [Company Name] are specifically engineered to deliver optimal performance in various material handling environments. The use of HDPE material ensures that the idlers are resistant to corrosion, abrasion, and wear, making them suitable for use in even the most demanding conditions. Additionally, their lightweight construction reduces energy consumption and contributes to a more sustainable and environmentally-friendly operation.One of the key advantages of Hdpe Conveyor Idlers is their low maintenance requirements. Unlike traditional steel idlers, which often need frequent lubrication and replacement due to wear and tear, Hdpe Conveyor Idlers are designed to be virtually maintenance-free. This not only saves time and resources but also minimizes downtime and operational disruptions, leading to increased productivity and cost savings for the end-users.Furthermore, Hdpe Conveyor Idlers offer excellent impact resistance, ensuring smooth and efficient operation even when handling heavy or abrasive materials. This durability and reliability significantly contribute to the longevity of conveyor systems, reducing the need for frequent repairs and replacements.In addition to their functional benefits, Hdpe Conveyor Idlers also contribute to a safer working environment. The lightweight nature of the idlers makes installation and maintenance safer and easier for personnel, reducing the risk of workplace accidents and injuries. This focus on safety aligns with [Company Name]'s commitment to providing solutions that not only improve efficiency but also prioritize the well-being of workers.The introduction of Hdpe Conveyor Idlers has been widely praised by industry experts and customers alike. The idlers have proven to be a cost-effective alternative to traditional steel idlers, offering long-term savings and improved performance. Furthermore, [Company Name] has provided comprehensive support and technical expertise to ensure seamless integration and operation of the Hdpe Conveyor Idlers in various material handling applications.With the increasing demand for efficient and sustainable material handling solutions, Hdpe Conveyor Idlers are set to play a crucial role in shaping the future of the industry. [Company Name]'s commitment to innovation and excellence has positioned them as a trusted partner for companies looking to optimize their conveyor systems and maximize operational efficiency.In conclusion, Hdpe Conveyor Idlers by [Company Name] represent a significant advancement in the material handling industry. Their superior performance, durability, and sustainability make them a preferred choice for companies looking to enhance their conveyor systems. As the industry continues to evolve, [Company Name] remains at the forefront of delivering innovative solutions that drive progress and success for its customers.

Innovative Corrugated Conveyor Belt System Streamlines Transport Operations

Corrugated Belt Conveyor: The Ultimate Solution for Material HandlingMaterial handling has become a crucial aspect of the manufacturing sector, where precise automation and movement of products are vital for an efficient operation. To meet the production demand and increase efficiency, industries are constantly looking for innovative solutions that can cater to their needs. In this regard, one such innovation that has taken the industry by storm is the corrugated belt conveyor.A corrugated belt conveyor is a type of conveyor that is made using a corrugated pattern of ridges and grooves on its surface. These belts are usually constructed of rubber, PVC, or some other durable material that can withstand the stress of movement and heavy loads. The corrugated pattern of the belt helps to increase the grip on the products that are being transported, reducing the chances of slippage or damage.The corrugated belt conveyors are versatile and can be used in a wide variety of industries, including food and beverages, pharmaceuticals, packaging, and many more. They can transport products of varied sizes and shapes, allowing the manufacturers to customize the conveyor according to their needs.The corrugated belt conveyor is not only efficient but also environmentally friendly. It is designed to reduce energy consumption and minimize carbon footprint by using energy-efficient motors and inverters. This conveyor reduces the manual labor required in material handling and ensures that the quality of the products is maintained throughout the production process.Several companies offer corrugated belt conveyors, but one of the leading names in this field is {removed brand name}. Founded in 2005, the company has been providing its customers with high-quality material handling solutions. From designing to manufacturing, the company offers a complete solution for all the material handling requirements of its clients.The corrugated belt conveyors provided by {removed brand name} are equipped with state-of-the-art technologies that make them one of the best in the market. The company offers a wide range of options for belt types, sizes, and materials to cater to the specific needs of customers. They also provide customized solutions as per the client's requirements and budget.The corrugated belts used in the conveyors provided by {removed brand name} have a unique design that ensures durability and low maintenance. The belts are equipped with a special tensioning system that ensures smooth operation and longer service life. The company also offers after-sales services to its customers to ensure that their conveyors continue to operate efficiently.{Removed brand name} is committed to providing its customers with high-quality and efficient material handling solutions. The company is constantly investing in new technologies and manufacturing processes to ensure that it stays ahead of the competition. Their focus on innovation, quality, and customer satisfaction has made them one of the leading names in the industry.In conclusion, the corrugated belt conveyor has revolutionized the material handling industry by providing a solution that is not only efficient but also environmentally friendly. {Removed brand name} is one of the leading manufacturers of these conveyors, providing its clients with customized solutions and unparalleled services. With the increasing demand for automation in the manufacturing sector, the corrugated belt conveyors are sure to become even more popular in the coming years.

Tail Pulley for Belt Conveyors: A Complete Guide

The {Company Name} has recently announced the development of a new belt conveyor tail pulley, adding to their extensive range of conveyor components. The company has been a leading manufacturer of conveyor systems and components for over 20 years, specializing in providing high-quality and customized solutions for a wide range of industries.The new belt conveyor tail pulley is designed to improve efficiency and reliability in conveyor systems, offering a durable and high-performance solution for the mining, aggregate, and bulk material handling industries. The tail pulley plays a crucial role in the operation of a conveyor system, providing the necessary tension and support for the conveyor belt to function effectively.{Company Name}’s belt conveyor tail pulley is constructed using high-quality materials and advanced manufacturing techniques to ensure maximum durability and performance. The pulley features a heavy-duty design, with a solid steel construction and precision-machined components to withstand the demands of heavy-duty applications. In addition, the pulley is equipped with an efficient bearing system to minimize friction and wear, contributing to the overall reliability and longevity of the conveyor system.The design of the new tail pulley also focuses on ease of installation and maintenance, with features such as a removable end plate and self-cleaning mechanism to facilitate quick and hassle-free maintenance procedures. This is in line with {Company Name}’s commitment to providing practical and user-friendly solutions for their customers, enhancing the overall operational efficiency and productivity of their conveyor systems.Furthermore, the new belt conveyor tail pulley is available in a variety of sizes and configurations to accommodate different conveyor designs and requirements, providing customers with the flexibility to tailor the pulley to their specific applications. This customization capability reflects {Company Name}’s dedication to meeting the unique needs of their customers and delivering solutions that are perfectly suited to their operational challenges.In addition to the new belt conveyor tail pulley, {Company Name} offers a comprehensive range of conveyor components, including idlers, pulleys, and accessories, all designed to meet the highest industry standards for quality and performance. The company’s expertise in conveyor systems is backed by a team of skilled engineers and technicians who are committed to providing expert advice and support to customers, ensuring that they receive the most effective solutions for their material handling requirements.With their extensive experience and technical capabilities, {Company Name} has established a strong reputation for delivering reliable and innovative conveyor solutions to a global customer base. The addition of the new belt conveyor tail pulley further strengthens the company’s position as a trusted partner for businesses in the mining, aggregate, and bulk material handling industries, providing them with the confidence to optimize their conveyor systems for maximum efficiency and productivity.As {Company Name} continues to expand their product offerings and enhance their capabilities, they remain dedicated to upholding their commitment to quality, innovation, and customer satisfaction. The development of the new belt conveyor tail pulley is a testament to the company’s ongoing efforts to provide cutting-edge solutions that address the evolving needs of their customers and the industry as a whole. With a focus on performance, reliability, and customization, {Company Name} is poised to remain a leader in the conveyor systems market for years to come.

New Retractable Underground Belt Conveyor System Provides Efficient Material Handling

Innovative Retractable Underground Belt Conveyor Revolutionizes Mining Industry The mining industry has long been known for its rugged and challenging work environments, and the need for innovative solutions to improve safety and efficiency is constantly growing. With this in mind, [Company Name] is revolutionizing the mining industry with its innovative Retractable Underground Belt Conveyor. This groundbreaking technology is poised to transform the way materials are transported underground, making mining operations safer and more efficient than ever before.[Company Name] is a leading provider of cutting-edge solutions for the mining industry, with a strong focus on technological innovation and sustainability. With a rich history of delivering high-quality equipment and services, the company has earned a reputation for excellence and reliability in the industry.The Retractable Underground Belt Conveyor is a game-changing technology that addresses some of the most pressing challenges in underground mining. By utilizing a retractable design, this conveyor system can easily adapt to the changing needs of the mine, allowing for seamless transportation of materials in various directions and configurations. This flexibility not only improves operational efficiency but also enhances safety by reducing the need for manual handling of materials in confined spaces.One of the key features of the Retractable Underground Belt Conveyor is its ability to be fully integrated into the mine's existing infrastructure. This allows for easy installation and seamless operation, minimizing downtime and maximizing productivity. The conveyor system is also designed to withstand the harsh conditions of underground mining, with robust construction and reliable performance even in the most challenging environments.The innovative design of the Retractable Underground Belt Conveyor is a result of [Company Name]'s commitment to research and development, as well as its dedication to meeting the evolving needs of the mining industry. By leveraging advanced technology and engineering expertise, [Company Name] has created a solution that sets a new standard for efficiency, safety, and sustainability in underground mining operations.In addition to its technological innovation, [Company Name] is also committed to sustainability and environmental responsibility. The Retractable Underground Belt Conveyor is designed to minimize energy consumption and reduce environmental impact, making it a truly sustainable solution for modern mining operations. By embracing a holistic approach to innovation, [Company Name] is not only driving progress in the mining industry but also contributing to a more sustainable future for the planet.The introduction of the Retractable Underground Belt Conveyor has already garnered significant interest from mining companies around the world. With its potential to transform underground mining operations, this innovative technology is set to make a lasting impact on the industry. As [Company Name] continues to push the boundaries of what is possible in mining technology, it is clear that the Retractable Underground Belt Conveyor is just the beginning of a new era of innovation and progress in the mining industry.In conclusion, the Retractable Underground Belt Conveyor from [Company Name] represents a significant leap forward for the mining industry. By combining advanced technology, robust construction, and a commitment to sustainability, [Company Name] has created a solution that addresses some of the most pressing challenges in underground mining. As the industry continues to evolve, the Retractable Underground Belt Conveyor is poised to play a key role in driving progress and shaping the future of mining operations around the world.

Discover the Benefits of Tabletop Chain Conveyors for Your Business

Tabletop Chain Conveyor Enhances Efficiency in Material HandlingIn a world where efficiency and productivity are key components for success, companies are constantly seeking innovative solutions to improve their processes. One such solution that has been gaining traction in the manufacturing and logistics industry is the tabletop chain conveyor. This advanced material handling system has proven to be a game-changer for businesses looking to streamline their operations and maximize throughput.The tabletop chain conveyor, offered by {}, is a versatile and reliable solution for handling a wide range of products in various industries. Its modular design and flexible configuration make it suitable for transporting products in a straight line, curves, and inclines, making it a perfect fit for facilities with complex layouts.One of the key advantages of the tabletop chain conveyor is its ability to handle heavy loads with ease. This is particularly important for industries such as automotive manufacturing, food processing, and warehousing, where large and bulky items need to be transported efficiently. The conveyor's robust construction and precision engineering allow it to withstand the rigors of demanding industrial environments, ensuring a long service life and minimal maintenance requirements.The seamless operation of the tabletop chain conveyor is also a significant benefit for businesses looking to optimize their workflows. With its smooth and consistent movement, the conveyor can effectively minimize the risk of product damage while ensuring a steady flow of materials throughout the production or distribution process. This not only improves overall efficiency but also enhances the safety of the working environment for operators and personnel.Furthermore, the tabletop chain conveyor is equipped with advanced control systems, such as variable speed drives and automated routing capabilities, which enable precise handling of products and seamless integration with other equipment. This level of automation not only reduces the reliance on manual labor but also allows for seamless coordination with upstream and downstream processes, resulting in a more synchronized and efficient operation.In addition to its technical capabilities, the tabletop chain conveyor is designed with hygiene and cleanliness in mind, making it well-suited for use in food and beverage processing facilities. The conveyor's smooth and easy-to-clean surfaces, along with its washdown-compatible materials, ensure compliance with stringent sanitation standards, providing a high level of confidence in product safety and quality.As a leading provider of material handling solutions, {} is committed to delivering innovative and reliable products that meet the evolving needs of modern businesses. With a strong focus on customer satisfaction and continuous improvement, the company has established itself as a trusted partner for companies seeking to optimize their operations and achieve sustainable growth.By offering a comprehensive range of conveyor systems, including the tabletop chain conveyor, {} empowers businesses to enhance their productivity, minimize downtime, and ultimately, gain a competitive edge in today's dynamic market landscape. With a team of experienced engineers and industry experts, the company also provides personalized consultation and support to help customers select the right solution for their specific requirements.In conclusion, the tabletop chain conveyor has emerged as a valuable asset for businesses looking to elevate their material handling capabilities. Its efficiency, versatility, and reliability make it a highly sought-after solution for a diverse range of applications, from manufacturing and packaging to distribution and logistics. With the support of leading providers like {}, companies can harness the true potential of this advanced conveyor system and drive sustainable success in their operations.