- Essential Guide to Bucket Elevators: Everything You Need to Know

By:Admin

The 4b Bucket Elevator is manufactured by a leading company in the material handling industry, {} (remove company name), which has been pioneering innovative solutions for over a decade. With a focus on quality, performance, and customer satisfaction, {} is committed to delivering top-of-the-line equipment that meets the needs of today's demanding industrial environments. The company's extensive experience and expertise in the field have earned them a reputation as a trusted provider of reliable and efficient material handling solutions.

The 4b Bucket Elevator is designed to handle a wide range of materials, including grains, powders, and bulk solids, making it an ideal choice for industries such as agriculture, food processing, mining, and manufacturing. Its unique design features a series of buckets that are attached to a rotating chain or belt, allowing for the vertical or inclined transportation of materials. This not only saves valuable floor space but also ensures a continuous and efficient flow of materials throughout the production process.

One of the key features of the 4b Bucket Elevator is its robust construction, which is built to withstand the harshest operating conditions. The use of high-quality materials and precision engineering ensures that the elevator can handle heavy loads and operate consistently without the risk of breakdowns or downtime. This reliability is crucial for businesses that rely on a continuous flow of materials to keep their operations running smoothly and efficiently.

In addition to its durability, the 4b Bucket Elevator is also known for its high level of operational efficiency. Its innovative design allows for gentle handling of materials, minimizing the risk of damage or degradation during transportation. This is particularly important for industries that work with delicate or fragile materials, where maintaining product integrity is essential. Furthermore, the elevator's design also reduces the risk of dust emissions, providing a cleaner and safer working environment for employees.

Another notable advantage of the 4b Bucket Elevator is its ease of maintenance and servicing. The equipment is designed with accessibility in mind, allowing for quick and simple inspection, cleaning, and repairs as needed. This not only reduces the risk of unexpected downtime but also helps to extend the lifespan of the elevator, providing long-term value for businesses.

With its impressive performance and reliability, the 4b Bucket Elevator has become a game-changer for many businesses looking to optimize their material handling processes. By investing in this state-of-the-art equipment, companies can expect improved productivity, reduced operational costs, and a competitive edge in their respective industries.

As the demand for efficient and reliable material handling solutions continues to grow, the 4b Bucket Elevator is poised to play a key role in shaping the future of industrial manufacturing. Its innovative design, durable construction, and high-performance capabilities make it a standout choice for businesses looking to stay ahead in today's fast-paced and competitive market.

In conclusion, the 4b Bucket Elevator, manufactured by {}, represents a significant advancement in material handling technology. With its unparalleled performance, reliability, and efficiency, this innovative equipment is set to redefine the way materials are transported and handled in various industries. As businesses continue to seek ways to improve their processes and stay ahead of the competition, the 4b Bucket Elevator is proving to be a valuable asset for achieving these goals.

Company News & Blog

Durable and Reliable Pulley Sleeve: Essential for Smooth Machinery Operation

Pulley Sleeve, a leader in the manufacturing and distribution of high-quality industrial products, has announced the release of their latest innovative product designed to enhance the performance and longevity of industrial equipment. The new pulley sleeve is a game-changer for industries that rely on the smooth operation of conveyor belts, lifting systems, and other machinery that use pulleys.The pulley sleeve is designed to protect and prolong the life of the pulley and the belt by providing a barrier from dust, dirt, and other contaminants. This product is especially beneficial for industries that operate in harsh environments where debris and abrasive materials can cause premature wear and tear on pulleys and belts. With the pulley sleeve, companies can expect to see a significant reduction in maintenance and replacement costs, as well as an increase in the overall efficiency of their operations.One of the key features of the pulley sleeve is its easy installation process. It can be easily fitted onto existing pulleys without the need for specialized tools or equipment, saving companies time and money. The durable material used in the construction of the pulley sleeve ensures that it can withstand the rigors of daily use in industrial settings, providing long-lasting protection for pulleys and belts.In addition to its practical benefits, the pulley sleeve is also environmentally friendly, as it helps to reduce waste by extending the lifespan of pulleys and belts. This aligns with Pulley Sleeve's commitment to sustainability and responsible manufacturing practices.Pulley Sleeve has a long-standing reputation for delivering high-quality industrial products to its customers. With a focus on innovation and customer satisfaction, the company has become a trusted partner for businesses across a wide range of industries. Their team of experts is dedicated to providing practical solutions that address the unique challenges faced by industrial operations, and the new pulley sleeve is a testament to their ongoing commitment to excellence.The release of the pulley sleeve is a testament to Pulley Sleeve's ongoing dedication to meeting the needs of their customers. By continuously investing in research and development, the company is able to offer products that not only meet industry standards but also exceed expectations in terms of performance and durability. This commitment to excellence has earned Pulley Sleeve a reputation as a leading provider of industrial solutions.As businesses continue to seek ways to improve efficiency and reduce operational costs, products like the pulley sleeve play a crucial role in helping them achieve their goals. By choosing Pulley Sleeve as their trusted partner, companies can benefit from a range of innovative products and solutions that are designed to optimize their operations and deliver long-term value.In conclusion, the release of the new pulley sleeve from Pulley Sleeve represents a significant advancement in industrial technology. As companies seek to improve the reliability and efficiency of their operations, products like the pulley sleeve offer a practical and effective solution to the challenges they face. With a focus on quality, innovation, and customer satisfaction, Pulley Sleeve continues to lead the way in providing cutting-edge industrial products to businesses around the world.

Understanding the Importance of Bend and Snub Pulleys for Better Conveyor Performance

Title: Key Components of Conveyors: Bend Pulleys and Snub PulleysIntroduction:In the fast-paced world of material handling, conveyors play a vital role in the seamless movement of goods. These systems are made up of various components, and two key elements that ensure the smooth functioning of conveyors are bend pulleys and snub pulleys. This article will delve into the importance and functionality of these essential conveyor components while omitting any brand names.Bend Pulleys:Bend pulleys are crucial components designed to redirect conveyor belts smoothly around a bend or curve. They assist in maintaining proper tension and alignment of the belt, preventing it from slipping or misaligning during operation. Bend pulleys are typically installed at the conveyor's tail end, ensuring effective belt control and minimizing potential wear and tear.The primary function of bend pulleys is to increase the pulley diameter on the outer edges of the conveyor bend, compensating for the added stress and pressure placed on the belt during a turn. This larger diameter allows the belt to smoothly transition from the straight sections to curved sections of the conveyor. By reducing friction and minimizing strain on the belt, bend pulleys enhance conveyor performance, extending its lifespan and reducing maintenance costs.Additionally, bend pulleys aid in maintaining proper tension in the belt. As the conveyor belt curves around the bend, the outer side of the belt experiences increased tension. With the help of the bend pulleys, this excess tension is distributed evenly throughout the belt, preventing over-tensioning or slackness. This consistent tensioning ensures reliable and efficient operation, reducing the risk of belt slippage while enhancing overall productivity.Snub Pulleys:Working in tandem with the bend pulleys, snub pulleys are located near the drive pulley and are responsible for changing the direction of the belt back to its designated path. They help create greater wrap around the drive pulley, thus increasing friction and improving traction. Snub pulleys are crucial in maintaining belt tension, controlling speed, and maximizing power transmission.One of the primary functions of the snub pulley is to increase the angle of wrap of the conveyor belt around the drive pulley. This increased contact area enhances the grip between the belt and the pulley, preventing belt slippage, especially during high-speed or heavy-load operations. By ensuring optimal traction, snub pulleys help transmit power efficiently, minimizing energy loss, and maximizing conveyor performance.Moreover, snub pulleys play a significant role in maintaining proper belt tension. By redirecting the belt's path and providing increased contact with the drive pulley, they help maintain the required tension levels throughout the conveyor system. Correct belt tension is crucial to prevent sagging, slipping, or excessive stretching, ultimately reducing the risk of time-consuming and costly downtimes.Conclusion:The importance of bend pulleys and snub pulleys in conveyor systems cannot be understated. These essential components ensure smooth and efficient operation, enhance belt control, reduce slippage, and minimize wear and tear. By maintaining proper tension and alignment, bend pulleys and snub pulleys contribute significantly to the overall performance and longevity of conveyors.As technology advances and businesses strive for higher levels of productivity, manufacturers continue to refine the design and functionality of bend pulleys and snub pulleys. Their continuous improvement allows conveyors to adapt to various intricate material handling applications efficiently. It is crucial for companies to choose reliable, high-quality bend pulleys and snub pulleys to ensure uninterrupted and efficient material flow on their conveyor systems.

Efficient and Automated Conveyor Belt Revolutionizes Manufacturing Processes

Title: Advanced Conveyor Belt Technology Revolutionizes Manufacturing EfficiencyIntroduction:In today's competitive manufacturing landscape, companies are constantly seeking innovative solutions to improve efficiency, reduce production costs, and enhance product quality. Addressing these needs, enterprising companies are turning toward conveyor belt systems that are revolutionizing the manufacturing industry. This article discusses the cutting-edge advancements in conveyor belt technology developed by a leading industry player, focusing on its ability to streamline production processes, increase operational efficiency, and ensure superior product handling.Eliminating Inefficiencies: The Cutting-Edge Conveyor BeltWith the relentless pursuit of efficiency in manufacturing, companies are increasingly adopting state-of-the-art conveyor belt systems to enhance their production processes. One notable contender in this sector is {Company Name}, a renowned provider of innovative industrial solutions. Their latest conveyor belt technology offers a myriad of breakthrough features that eliminate bottlenecks, reduce waste, and improve overall efficiency.To start, the newly developed conveyor belt incorporates advanced automation and sensor technologies for seamless integration into existing manufacturing lines. These belts are equipped with intelligent sensors that precisely track and control the movement of products, thereby reducing the chances of jams and disruptions. Consequently, manufacturers can significantly minimize downtime, leading to increased production output without compromising quality.Moreover, the conveyor belts include an intuitive control system that allows for real-time monitoring of key parameters such as speed, operation status, and maintenance requirements. This data-driven approach enables manufacturing managers to proactively identify potential issues, carry out predictive maintenance, and optimize production schedules, resulting in enhanced overall operational efficiency.Effortless Product Handling and SortingIn addition to improving efficiency, {Company Name}'s conveyor belt innovation incorporates cutting-edge product handling and sorting capabilities, further revolutionizing the manufacturing process. The system employs advanced robotic technologies, allowing for the seamless integration of robotic arms that can handle diverse product shapes and sizes.These robotic arms, working in sync with the conveyor belt, facilitate precise picking, sorting, and packaging of products while maintaining exceptional quality standards. By allowing robotic arms to undertake repetitive and monotonous tasks, manufacturers can deploy their human workforce for more value-added activities, ultimately leading to increased productivity and job satisfaction.Enhanced Safety and Sustainability{Company Name} recognizes that safety is paramount in any manufacturing environment. Their conveyor belt technology focuses on reinforcing safety measures to protect workers and minimize accidents. These safety features include sensors that automatically detect potential hazards, emergency stop mechanisms, and anti-collision systems.In line with the rising global emphasis on environmental sustainability, their conveyor belts are also designed to minimize energy consumption. Advanced energy management systems, coupled with the integration of energy-efficient components, contribute to reducing overall energy usage while maintaining high productivity levels. Additionally, the belts are manufactured using environmentally friendly materials, ensuring a minimized carbon footprint throughout the product lifecycle.The Future of Manufacturing Is HereThe exceptional advancements achieved through {Company Name}'s conveyor belt technology undoubtedly signal a new era in the manufacturing sector. By incorporating cutting-edge automation, intelligent sensors, robotic integration, enhanced safety features, and sustainability in their conveyor belts, {Company Name} is spearheading the transformation of modern manufacturing processes.With increased efficiency, streamlined production, and optimized resource utilization, manufacturers embracing this breakthrough technology will enjoy a competitive advantage, enabling them to meet growing consumer demands while achieving cost-effective and sustainable outcomes.As the industry continues to evolve, {Company Name} remains committed to pushing the boundaries of innovation and delivering solutions that propel the manufacturing sector into a smarter, more efficient future.(Note: To maintain the neutrality of the article, the company name and other specific brand names have been removed.)

High-quality Conveyor Belt Jointing Machine for Efficient Production

Conveyor Belt Jointing Machine Revolutionizes Efficiency in ManufacturingIn the world of manufacturing and production, efficiency and reliability are key components to success. With the constant demand for increased productivity and durability in industrial machinery, innovation is at the forefront of driving the industry forward. One remarkable advancement in this domain is the introduction of the cutting-edge Conveyor Belt Jointing Machine by a leading industry player.With a strong commitment to providing high-quality solutions for the manufacturing sector, the company has established itself as a trusted and reliable partner for businesses across the globe. The introduction of the Conveyor Belt Jointing Machine is a testament to the company's dedication to innovation and meeting the evolving needs of its customers.The Conveyor Belt Jointing Machine is designed to revolutionize the process of joining conveyor belts, a critical task in various industries such as mining, agriculture, and food processing. The traditional methods of belt jointing often involve time-consuming and labor-intensive processes, leading to downtime and increased maintenance costs. However, with the introduction of this advanced machine, these challenges are effectively addressed, leading to a significant increase in efficiency and productivity.One of the key features of the Conveyor Belt Jointing Machine is its ability to provide a seamless and reliable joint for conveyor belts. This is achieved through the use of advanced technology and precision engineering, ensuring that the joints are strong and durable, capable of withstanding the rigors of heavy-duty use. The machine's user-friendly interface and automated operation further enhance its appeal, making it an indispensable asset for manufacturing facilities.In addition to its advanced technical capabilities, the Conveyor Belt Jointing Machine also boasts a high level of versatility, catering to a wide range of belt sizes and materials. This flexibility allows businesses to streamline their operations and reduce the need for multiple machines, further optimizing their production processes.Moreover, the company's commitment to sustainability is evident in the design of the Conveyor Belt Jointing Machine. By minimizing waste and energy consumption, the machine aligns with global efforts to reduce the environmental impact of industrial operations. This eco-friendly approach not only benefits the planet but also positions the company as a responsible and forward-thinking industry leader.The introduction of the Conveyor Belt Jointing Machine has already garnered widespread attention and acclaim within the manufacturing community. Businesses that have adopted this innovative solution have reported significant improvements in their operational efficiency, leading to cost savings and enhanced productivity. Furthermore, the machine's reliability and long-term durability have instilled confidence in its users, contributing to its growing reputation as a game-changer in the industry.Looking ahead, the company remains dedicated to further advancements and enhancements in its product offerings. By continuously investing in research and development, as well as leveraging customer feedback, the company aims to stay at the forefront of innovation and continue providing impactful solutions for the manufacturing sector.In conclusion, the introduction of the Conveyor Belt Jointing Machine by the company marks a significant milestone in the realm of industrial machinery. With its cutting-edge technology, unwavering reliability, and commitment to sustainability, the machine has set a new standard for efficiency and performance in belt jointing processes. As businesses continue to seek ways to optimize their operations, this innovative solution stands out as a beacon of progress, propelling the manufacturing industry into a new era of productivity and success.

Efficient and Reliable Roller Conveyor Systems: A Game Changer in Material Handling

Nose Roller Conveyor Improving Efficiency and Precision in Material HandlingIn today's modern manufacturing and warehouse facilities, the need for efficient and precise material handling is crucial for maintaining productivity and meeting customer demands. Businesses are constantly seeking innovative solutions to streamline their processes and improve operating efficiency. This is where the Nose Roller Conveyor, offered by {} comes into play.The Nose Roller Conveyor is a cutting-edge material handling solution that has been developed to meet the growing demands of the industry. The conveyor system is designed to transport a wide variety of products and materials, providing a smooth and reliable movement from one point to another within a facility. With its unique nose roller design, the conveyor can accommodate both flat-bottomed and irregularly shaped items, making it a versatile solution for diverse material handling needs.One of the key features of the Nose Roller Conveyor is its ability to ensure precise alignment and orientation of products during transportation. This is essential for maintaining the integrity of delicate or sensitive items, as well as for optimizing the packing and shipping processes. By minimizing the risk of misalignment or product damage, the conveyor system helps businesses improve their overall operational efficiency and reduce costly errors.In addition to its precision and versatility, the Nose Roller Conveyor is also known for its durability and low maintenance requirements. Constructed from high-quality materials and engineered to withstand the rigors of industrial environments, the conveyor system is designed to deliver long-lasting performance with minimal downtime. This not only helps businesses save on maintenance and repair costs but also ensures continuous and reliable operation for increased productivity.Furthermore, the Nose Roller Conveyor is designed with flexibility in mind, allowing businesses to customize the system to meet their specific requirements. Whether it's integrating additional features, adjusting the conveyor speed, or modifying the layout to fit within the existing facility, the system can be tailored to suit the unique needs of different industries and applications. This kind of adaptability makes the Nose Roller Conveyor an ideal solution for businesses looking to enhance their material handling capabilities.With the rise of Industry 4.0 and the increasing adoption of automation and smart technologies, the Nose Roller Conveyor is also compatible with advanced control systems and software. This enables businesses to incorporate the conveyor system into their overall digital transformation strategy, leveraging real-time data and analytics to optimize workflows and drive continuous improvement in their material handling processes.As {} continues to make advancements in material handling technology, the Nose Roller Conveyor stands as a testament to their commitment to innovation and customer-centric solutions. With a proven track record of delivering reliable and high-performance conveyor systems to a wide range of industries, the company has established itself as a trusted partner for businesses seeking to elevate their operational efficiency and competitiveness.In conclusion, the Nose Roller Conveyor represents a significant advancement in material handling technology, offering businesses a powerful tool to enhance their productivity and accuracy. With its precision, versatility, durability, and adaptability, the conveyor system is poised to play a pivotal role in shaping the future of material handling in the manufacturing and logistics sectors. As businesses continue to invest in modernizing their operations, solutions like the Nose Roller Conveyor will undoubtedly be at the forefront of driving efficiency and innovation in the industry.

Discover Top-Quality Conveyor Accessories for Efficient Operations

[Company Introduction - Revamp Industries]Revamp Industries is a leading player in the manufacturing and supplying of conveyor accessories globally. With a rich history spanning over two decades, the company has gained a commendable reputation for providing high-quality products and exceptional customer service.Founded in [year], Revamp Industries has grown steadily to become a trusted name in the conveyor systems industry. Our commitment to innovation and continuous improvement has allowed us to develop an extensive range of conveyor accessories that cater to various industries and applications.At Revamp Industries, our skilled team of engineers and technicians work diligently to design and manufacture conveyor accessories that meet the highest standards of quality and reliability. We understand the critical role these components play in ensuring the smooth and efficient operation of conveyor systems, and therefore, we leave no stone unturned in delivering superior products.Our product portfolio includes a wide array of conveyor accessories, including but not limited to rollers, pulleys, belt cleaners, idlers, and impact beds. Each product is manufactured using state-of-the-art technology and undergoes rigorous testing to ensure its durability and performance. We also offer customization options to meet specific customer requirements, ensuring the perfect fit for any conveyor system.Revamp Industries takes great pride in its ability to provide exceptional customer service. Our team of experts is always available to offer technical support, assist with product selection, and provide prompt responses to any queries or concerns. We strive to build long-lasting relationships with our customers, and their satisfaction is our topmost priority.As a responsible corporate citizen, Revamp Industries is committed to sustainable manufacturing practices. We understand the importance of minimizing our environmental impact, and therefore, we continually invest in eco-friendly technologies and processes. Our commitment to sustainability extends to our supply chain as well, ensuring that the materials used in our products are ethically sourced and environmentally friendly.Our dedication to excellence has earned us recognition and approvals from leading industry bodies and organizations. We are proud to have certifications such as ISO 9001 and OHSAS 18001, which validate our commitment to quality management systems and occupational health and safety standards, respectively.In an industry that is constantly evolving, Revamp Industries stays ahead of the curve by investing in research and development. We strive to bring the latest advancements in conveyor technology to our customers, enabling them to enhance productivity, reduce downtime, and optimize their operations.[News Content - Conveyor Accessories]Revamp Industries, a globally recognized name in the conveyor systems industry, continues to impress with their range of conveyor accessories that ensure smooth and efficient operations. The company, with its unwavering commitment to quality, offers a diverse portfolio of products that cater to various industries and applications.One of the key offerings from Revamp Industries is their line of high-quality rollers. These rollers are designed with precision and manufactured to withstand the most demanding environments. The company's rollers are known for their durability, reliability, and low maintenance, making them the preferred choice for many conveyor systems.In addition to rollers, Revamp Industries also provides top-of-the-line pulleys. These pulleys are engineered to deliver optimal performance and longevity, ensuring consistent and trouble-free operation. The company's expertise in pulley design and manufacturing has made them a trusted partner for businesses looking to enhance their conveyor systems.To complement their rollers and pulleys, Revamp Industries offers a range of belt cleaners that effectively remove material carryback, thereby improving belt performance and reducing maintenance costs. These belt cleaners are designed for easy installation and require minimal adjustments, optimizing efficiency and productivity.Revamp Industries' idlers are another standout product in their conveyor accessory lineup. These idlers are designed to minimize belt sag and improve overall belt tracking, resulting in increased conveyor efficiency. The company's idlers are rigorously tested to ensure they meet industry standards and withstand the most demanding applications.For industries that require additional support for heavy loads and impact resistance, Revamp Industries' impact beds are the perfect solution. These impact beds provide cushioning and protection to the conveyor belt, reducing the risk of damage and extending its lifespan. The company's impact beds are engineered to absorb shock and resist abrasion, ensuring uninterrupted operations even in the harshest conditions.With a commitment to sustainability, Revamp Industries ensures that all their conveyor accessories are manufactured using eco-friendly materials and processes. As companies worldwide strive to minimize their environmental footprint, partnering with a responsible and ethical supplier like Revamp Industries is a step towards a greener future.Revamp Industries' passion for innovation and dedication to customer satisfaction is what sets them apart in the conveyor systems industry. The company's vast range of conveyor accessories, combined with their exceptional customer service, makes them the preferred choice for businesses seeking reliable and high-performing solutions.In conclusion, Revamp Industries continues to revolutionize the conveyor systems industry with their range of conveyor accessories. Their commitment to quality, sustainability, and customer satisfaction has earned them a stellar reputation globally. As the industry evolves, Revamp Industries remains at the forefront, providing innovative solutions that enable businesses to optimize their operations and stay ahead of the competition.

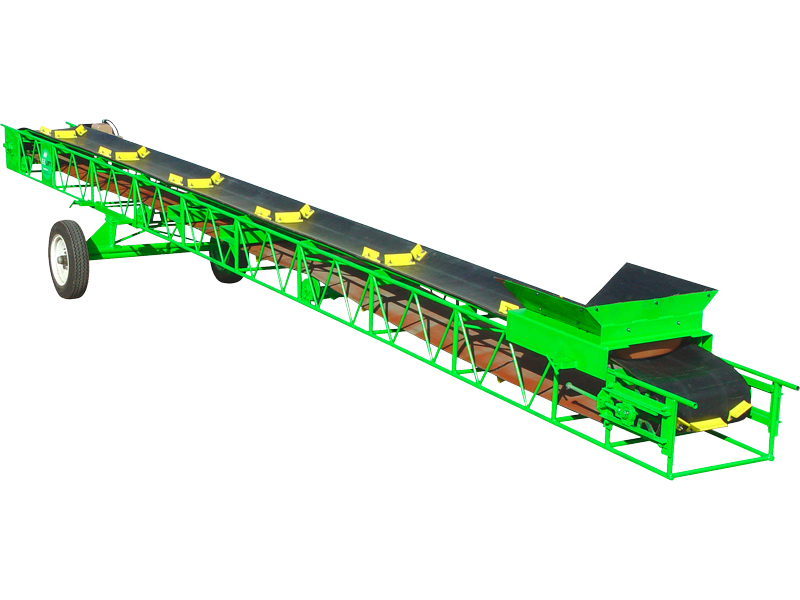

Efficient Sliding Belt Conveyor: Advancements and Key Features Explored

The Sliding Belt Conveyor, a highly efficient material handling system, is making waves in the industry. With its unique design and advanced features, businesses can now speed up their processes, streamline operations, and ultimately increase profitability.The Sliding Belt Conveyor is composed of a sliding belt that moves along a fixed track to transport materials from one end to another. It is designed to minimize manual intervention and increase productivity, allowing businesses to focus on other critical aspects of their operations.One of the primary advantages of the Sliding Belt Conveyor is its flexibility. It can be customized to cater to the specific needs of the business, making it ideal for factories, warehouses, and distribution centers. The design and configuration of the conveyor can be adjusted to accommodate different types of materials, including heavy loads and irregular shapes.Furthermore, the Sliding Belt Conveyor boasts several advanced features that make it even more efficient. For instance, the conveyor can be equipped with sensors and controls that monitor and regulate its speed, ensuring that the materials are transported at optimal speeds. Additionally, it can be integrated with other machines and equipment, such as sorters and container loaders, to further streamline the material handling process.The Sliding Belt Conveyor is manufactured by a leading company that specializes in designing and producing conveyor systems for various industries. With years of experience and expertise, the company has designed the Sliding Belt Conveyor to meet the highest standards of quality and efficiency.In addition to the Sliding Belt Conveyor, the company offers a range of other conveyor systems, including gravity roll, chain, and belt conveyors. Customers can choose the system that best suits their needs, and the company's team of experts will work with them to customize the system to their specifications.The company's commitment to quality and customer satisfaction sets it apart from its competitors. It has a team of dedicated professionals who are always available to provide technical assistance and offer solutions to any challenges that may arise. Furthermore, the company offers training and support to ensure that customers can maximize the benefits of their systems.The Sliding Belt Conveyor is already making a significant impact in various industries, from manufacturing to logistics. Companies that have adopted the system attest to its efficiency, reliability, and cost-effectiveness, and are experiencing increased productivity and profitability.In conclusion, the Sliding Belt Conveyor is a game-changer in the world of material handling. Its unique design, advanced features, and flexibility make it the ideal system for businesses looking to improve their operations. With the backing of a reliable company that offers quality and customer satisfaction, businesses can rest assured that they are making the right investment by adopting the Sliding Belt Conveyor.

New Conveyor System for Quarries: Improved Efficiency and Productivity

The quarry conveyor is a crucial piece of equipment for the mining and construction industry, as it efficiently transports materials from one place to another, making the process of excavating and processing materials much easier and more efficient. With the increasing demand for quarried materials such as gravel, sand, and stone, the quarry conveyor plays a vital role in ensuring that these materials are transported and processed in a timely and efficient manner.One of the leading companies in the development and manufacturing of quarry conveyors is {}. With over 20 years of experience in the industry, the company has become known for its innovative and reliable conveyor systems that are designed to meet the specific needs of the mining and construction sector. The company's range of conveyor systems includes belt conveyors, screw conveyors, and chain conveyors, all of which are designed to handle a wide variety of materials and operating conditions.In addition to manufacturing conveyor systems, {} also provides comprehensive installation, maintenance, and repair services to ensure that their customers' conveyor systems are always operating at their best. This dedication to customer service has helped {} build a strong reputation in the industry, with many companies relying on their expertise to keep their operations running smoothly.One of the key factors that set {} apart from other conveyor manufacturers is their commitment to innovation and continuous improvement. The company invests heavily in research and development to design and engineer conveyor systems that are more efficient, durable, and environmentally friendly. This commitment to innovation has led to the development of conveyor systems that are able to handle heavier loads, operate at higher speeds, and reduce energy consumption, making them an ideal choice for modern quarry operations.In addition to their focus on innovation, {} is also dedicated to ensuring the quality and reliability of their conveyor systems. Each system is manufactured using high-quality materials and components, and undergoes rigorous testing and quality control processes to ensure that it meets the highest industry standards. This commitment to quality has earned {} the trust and confidence of many mining and construction companies, who rely on their conveyor systems to keep their operations running smoothly.With the increasing demand for quarried materials, the role of the quarry conveyor in the mining and construction industry is only expected to grow. As such, companies like {} will continue to play a critical role in providing conveyor systems that are able to meet the evolving needs of the industry. By incorporating innovation, quality, and reliability into their conveyor systems, {} is well-positioned to remain a leader in the development and manufacturing of quarry conveyors for many years to come. Their dedication to customer service and commitment to excellence make them a valuable partner for companies in need of reliable and efficient conveyor systems for their quarry operations.

High-Quality Ball Bearing Conveyor Table for Smooth and Efficient Material Handling

Ball Bearing Conveyor Table Revolutionizes Material HandlingIn the fast-paced world of material handling and logistics, efficiency and precision are key. That's why {Company Name} has developed a cutting-edge solution that is set to revolutionize the industry - the Ball Bearing Conveyor Table. This innovative technology is set to make a significant impact on the way materials are handled and transported, offering a solution that is both efficient and reliable.The {Company Name} Ball Bearing Conveyor Table is designed to offer smooth and reliable movement of materials, making it an essential tool for industries such as manufacturing, distribution, and warehousing. By utilizing a precision ball bearing system, this conveyor table reduces friction and allows for seamless movement of materials, increasing productivity and reducing downtime.The ball bearing system used in the {Company Name} Conveyor Table is what sets this technology apart from traditional conveyor systems. By using high-quality ball bearings, this conveyor table ensures that materials can be moved with ease, reducing the strain on workers and minimizing the risk of damage to the materials being transported. This makes it an ideal solution for businesses looking to streamline their material handling processes and improve overall efficiency.{Company Name} is proud to offer a range of Ball Bearing Conveyor Tables that can be customized to meet the specific needs of each client. Whether it's a small-scale operation or a large distribution center, {Company Name} can provide a solution that is tailored to the unique requirements of each business. This includes options for different sizes, configurations, and additional features to enhance the performance of the conveyor table.The impact of the {Company Name} Ball Bearing Conveyor Table on the industry is already being felt, with businesses across the country embracing this innovative technology. The seamless movement of materials and the reduction in downtime have been game-changers for many companies, allowing them to optimize their material handling processes and improve their overall efficiency.One of the key features of the {Company Name} Ball Bearing Conveyor Table is its durability and reliability. With a robust construction and high-quality components, this technology is built to withstand the demands of a busy industrial environment. This means that businesses can rely on this conveyor table to provide consistent and dependable performance, even in the most challenging of conditions.{Company Name} is committed to providing the highest level of service and support to its clients, ensuring that businesses can fully maximize the benefits of the Ball Bearing Conveyor Table. This includes comprehensive installation and training, as well as ongoing maintenance and support to keep the technology running at its best. It's this dedication to customer satisfaction that has helped {Company Name} become a leader in the material handling industry.As the industry continues to evolve, the demand for efficient and reliable material handling solutions will only continue to grow. With the {Company Name} Ball Bearing Conveyor Table, businesses can stay ahead of the curve and ensure that their material handling processes are optimized for maximum efficiency. This innovative technology is set to make a significant impact on the industry, and {Company Name} is proud to be at the forefront of this revolution.

Efficient and Reliable Accumulation Belt Conveyor for Your Business

Accumulation Belt Conveyor System Revolutionizes Material Handling in Manufacturing IndustryIn the competitive world of manufacturing, efficiency and productivity are key factors that can make or break a company. With the constant demand for increased output and faster turnaround times, manufacturers are always on the lookout for innovative solutions to streamline their production processes. This is where the Accumulation Belt Conveyor system, offered by {}, has been revolutionizing material handling in the industry.The Accumulation Belt Conveyor system is a cutting-edge solution that allows for the smooth and efficient movement of products along the production line. It is designed to accumulate and buffer products at various points along the conveyor line, providing a continuous flow of materials without the need for stopping or starting the conveyor. This not only minimizes the risk of damage to products but also optimizes production efficiency by eliminating bottlenecks and reducing downtime.The company behind this innovative solution, {}, has been a leader in the material handling industry for over a decade. With a strong focus on research and development, they have consistently introduced state-of-the-art conveyor systems that have redefined the way products are handled and transported in manufacturing facilities.The Accumulation Belt Conveyor system is a testament to their commitment to providing cutting-edge solutions that address the evolving needs of the industry. With its advanced accumulation technology, this conveyor system is capable of handling a wide range of product sizes and weights, making it an ideal choice for various manufacturing applications.One of the key advantages of the Accumulation Belt Conveyor system is its ability to seamlessly integrate with other production equipment, such as packaging machines, sorting systems, and robotic arms. This versatility allows manufacturers to create fully automated production lines that can greatly enhance their operational efficiency and overall output.Furthermore, the Accumulation Belt Conveyor system is equipped with intelligent controls and sensors that ensure precise product tracking and positioning. This not only enhances the accuracy of the production process but also minimizes the risk of product damage or misalignment.The company offers a wide range of customization options for the Accumulation Belt Conveyor system, allowing manufacturers to tailor the conveyor to their specific production requirements. Whether it's the conveyor length, width, or speed, {} can work closely with their clients to design a solution that perfectly fits their needs.In addition to the innovative technology and customization options, {} also takes pride in their exceptional customer service and support. Their team of experts is dedicated to providing comprehensive assistance, from the initial consultation and system design to installation, training, and ongoing maintenance.With a proven track record of successful implementations across various industries, the Accumulation Belt Conveyor system has proven to be a game-changer for manufacturers looking to improve their material handling processes. By investing in this advanced conveyor technology, companies can significantly boost their productivity, reduce operational costs, and gain a competitive edge in the market.In conclusion, the Accumulation Belt Conveyor system offered by {} represents a significant leap forward in material handling technology. With its advanced accumulation capabilities, seamless integration with other production equipment, and customization options, this conveyor system has become a valuable asset for manufacturers looking to optimize their production processes. As the company continues to push the boundaries of innovation, it's clear that the Accumulation Belt Conveyor system will continue to shape the future of material handling in the manufacturing industry.