High-quality Hold Down Conveyor Wheels for Improved Stability and Performance

By:Admin

In the fast-paced world of material handling, efficiency is key. Companies are constantly searching for ways to streamline their processes and increase productivity. This is where Conveyor Hold Down Wheels play a crucial role. These small yet powerful components are the backbone of efficient material handling, ensuring smooth and reliable transportation of goods across various industries.

*** (company name) is a leading manufacturer of Conveyor Hold Down Wheels, with a proven track record of providing top-quality products to their customers. With over 20 years of experience in the industry, they have established themselves as a trusted name in the world of material handling.

Conveyor Hold Down Wheels may seem like a minor component in the grand scheme of things, but they play a significant role in ensuring the smooth operation of conveyor systems. These wheels are designed to keep the conveyor belt in place, preventing it from slipping or moving out of alignment during the transportation of goods. This is crucial in preventing costly downtime and ensuring the safe and efficient movement of materials throughout the facility.

The key to the success of Conveyor Hold Down Wheels lies in their design and construction. *** (company name) takes great pride in the quality of their products, using only the finest materials and the latest manufacturing techniques to ensure that their Conveyor Hold Down Wheels are built to last. This commitment to quality has earned them a reputation for producing some of the most reliable and durable hold down wheels on the market.

One of the standout features of *** (company name)’s Conveyor Hold Down Wheels is their versatility. These wheels are designed to be compatible with a wide range of conveyor systems, making them suitable for use in various industries, including manufacturing, distribution, and logistics. This versatility allows customers to easily integrate these hold down wheels into their existing conveyor systems, providing a seamless and cost-effective solution for improving material handling efficiency.

In addition to their standard range of Conveyor Hold Down Wheels, *** (company name) also offers custom solutions to meet the specific needs of their customers. Whether it's a unique size requirement, a specific material handling challenge, or a specialized application, their team of experts can work closely with clients to develop tailored solutions that address their individual needs.

Furthermore, *** (company name) is committed to providing exceptional customer service. Their knowledgeable and responsive team is dedicated to helping customers find the right hold down wheel solution for their specific requirements. From initial inquiries to after-sales support, *** (company name) strives to deliver a seamless and hassle-free experience for their customers, further solidifying their reputation as a trusted partner in the material handling industry.

As the demand for efficient material handling solutions continues to grow, the importance of reliable conveyor hold down wheels cannot be overstated. With their commitment to quality, versatility, and customer satisfaction, *** (company name) has established itself as a leader in this space. Their Conveyor Hold Down Wheels are the go-to choice for companies looking to optimize their material handling processes, improve productivity, and reduce downtime.

In conclusion, Conveyor Hold Down Wheels may seem like a small component, but they play a crucial role in ensuring the efficient and reliable transportation of goods in various industries. For companies looking to improve their material handling processes, partnering with a trusted manufacturer like *** (company name) is the key to success. With their top-quality products, custom solutions, and exceptional customer service, *** (company name) is poised to continue leading the way in the world of conveyor hold down wheels for years to come.

Company News & Blog

High-Quality Belt Scraper Blades for Effective Material Handling

The use of belt scraper blades is essential in the mining and bulk material handling industries, where the efficient and continuous operation of conveyor belts is crucial. These blades are designed to remove material buildup from the belt, ensuring smooth and uninterrupted flow of materials. With the increasing demand for high-quality belt scraper blades, one company that has been at the forefront of providing reliable and efficient solutions is {}.{} is a leading manufacturer and supplier of belt scraper blades, offering a wide range of products designed to meet the diverse needs of its customers. The company’s dedication to quality and innovation has set it apart in the industry, making it a trusted partner for many businesses around the world.One of the key factors that sets {} apart is its commitment to research and development. The company continuously invests in improving its products and developing new technologies to meet the evolving needs of the market. This dedication to innovation has allowed {} to offer some of the most advanced and effective belt scraper blades in the industry.Furthermore, {} takes pride in its focus on customer satisfaction. The company works closely with its clients to understand their specific requirements and provide tailored solutions that address their unique challenges. This customer-centric approach has earned {} a reputation for reliability and excellence in the industry.The company’s extensive product range includes a variety of belt scraper blades, each designed for specific applications and operating conditions. Whether it’s the removal of sticky materials, excessive carryback, or fine particles, {} offers solutions that are tailored to deliver optimum performance and efficiency.In addition to its high-quality products, {} also provides comprehensive technical support and after-sales service. The company’s team of experts is readily available to assist customers with installation, maintenance, and troubleshooting, ensuring that their belt scraper blades continue to deliver optimal performance over time.The dedication to quality and customer satisfaction has positioned {} as a preferred supplier for many businesses involved in mining and bulk material handling. The company’s commitment to excellence and continuous improvement has enabled it to build strong and long-lasting relationships with its customers, who rely on {} for their critical belt scraper blade needs.In addition to its focus on product quality and customer service, {} is also committed to sustainability and environmental responsibility. The company recognizes the importance of minimizing its environmental impact and actively seeks to develop products and processes that align with this goal. By choosing {} as their supplier, customers can be confident that they are partnering with a company that prioritizes sustainability and ethical business practices.As the demand for efficient and reliable belt scraper blades continues to grow, {} remains dedicated to meeting the needs of its customers and providing high-quality solutions that contribute to the success of their operations. With its focus on innovation, customer satisfaction, and sustainability, {} is well-positioned to remain a leader in the industry for years to come.In conclusion, {} has established itself as a trusted provider of belt scraper blades, offering a comprehensive range of high-quality products and exceptional customer support. The company’s commitment to innovation, customer satisfaction, and sustainability sets it apart in the industry, making it a preferred partner for businesses in the mining and bulk material handling sectors. With its dedication to excellence, {} is poised to continue leading the way in providing efficient and reliable belt scraper blade solutions.

Innovative Turning Belt Conveyor Technology Revolutionizes Material Handling Systems

The global material handling equipment company, [Company Name], has recently announced the launch of their innovative Turning Belt Conveyor. This new addition to their extensive product line is designed to provide efficient and reliable turning of transported items in a variety of industrial applications. With its advanced technology and high-quality construction, the Turning Belt Conveyor is set to revolutionize the way materials are handled and processed in manufacturing and distribution facilities worldwide.The Turning Belt Conveyor is a key component in the company's portfolio of material handling solutions. It offers the ability to smoothly and accurately change the direction of transported items without the need for manual intervention, thereby improving overall efficiency and productivity in material handling operations. This is particularly beneficial for industries such as food and beverage, pharmaceuticals, automotive, and logistics, where the seamless flow of materials is critical to maintaining production schedules and meeting customer demands.One of the key features of the Turning Belt Conveyor is its modular design, which allows for easy integration into existing conveyor systems. This means that businesses can incorporate the Turning Belt Conveyor into their operations without the need for significant reconfiguration or downtime, saving both time and money. Additionally, the conveyor is constructed with high-quality materials and components, ensuring long-term reliability and minimal maintenance requirements.“Our Turning Belt Conveyor is the result of extensive research and development, as well as valuable input from our customers,” said [Company Name]’s CEO. “We are confident that this product will make a significant impact on the material handling industry by providing a reliable and efficient solution for turning transported items. We are committed to delivering high-quality products that not only meet but exceed our customers' expectations, and the Turning Belt Conveyor is a testament to that commitment.”In addition to its advanced technology and reliability, the Turning Belt Conveyor is designed with a focus on safety. It is equipped with a range of safety features to ensure the protection of both the operators and the transported items. These features include emergency stop buttons, safety interlocks, and guards to prevent accidental contact with moving parts. As a result, businesses can have peace of mind knowing that their employees and products are safe during the material handling process.The launch of the Turning Belt Conveyor is in line with [Company Name]’s mission to provide comprehensive and innovative material handling solutions to their customers. With a strong focus on research and development, the company continues to introduce new products and advancements to meet the evolving needs of the industry. This commitment to innovation has solidified [Company Name]’s position as a leader in the material handling equipment market, with a reputation for delivering cutting-edge solutions that drive operational efficiency and profitability for their customers.In conclusion, the introduction of the Turning Belt Conveyor is set to bring about a significant change in the material handling industry. With its advanced technology, high-quality construction, and focus on safety, this new product from [Company Name] is poised to improve the efficiency and productivity of material handling operations in various industrial sectors. As the company continues to pioneer innovative solutions, the Turning Belt Conveyor stands as a testament to their dedication to driving the industry forward.

Efficient Stacker Reclaimer Bucket Wheel for Material Handling

The Stacker Reclaimer Bucket Wheel is a key component in the material handling process for industries such as mining, power generation, and manufacturing. This massive piece of equipment is used to stack and reclaim bulk materials such as coal, iron ore, and other minerals, allowing for efficient storage and processing of these valuable resources.One of the leading providers of Stacker Reclaimer Bucket Wheel technology is a global engineering company that has been at the forefront of material handling solutions for over 150 years. With a strong focus on innovation and quality, this company has established itself as a trusted partner for industries around the world.The Stacker Reclaimer Bucket Wheel offered by this company is designed to meet the specific needs of each customer, with customizable features and state-of-the-art technology. The company's team of experts works closely with clients to understand their requirements and provide tailored solutions that optimize efficiency and productivity.One of the key advantages of the Stacker Reclaimer Bucket Wheel offered by this company is its robust and durable design. Built to withstand the harsh conditions of industrial operations, this equipment is able to consistently handle large volumes of materials with minimal downtime. This reliability is essential for industries where uninterrupted production is crucial to success.In addition to its durability, the Stacker Reclaimer Bucket Wheel is also designed for ease of maintenance. With accessible components and advanced monitoring systems, this equipment helps to minimize the need for costly repairs and downtime, ensuring that operations can continue running smoothly.Another important feature of the Stacker Reclaimer Bucket Wheel is its efficiency in handling materials. With its high capacity and precision control systems, this equipment allows for quick and accurate stacking and reclaiming of bulk materials, enabling industries to streamline their processes and maximize throughput.Furthermore, the company's Stacker Reclaimer Bucket Wheel is designed with a focus on safety. With advanced safety features and comprehensive training programs, this equipment helps to protect workers and prevent accidents in the workplace, contributing to a secure and productive environment.The company's commitment to sustainability is also reflected in its Stacker Reclaimer Bucket Wheel technology. By optimizing the use of energy and resources, this equipment helps industries to minimize their environmental impact and operate in a more eco-friendly manner, aligning with the growing focus on sustainable practices.Overall, the Stacker Reclaimer Bucket Wheel offered by this company is a reliable, efficient, and sustainable solution for material handling in a wide range of industries. With its customizable design, durability, efficiency, and focus on safety and sustainability, this equipment is a valuable asset for companies seeking to optimize their operations and achieve long-term success.As industries continue to evolve and grow, the demand for reliable and efficient material handling solutions such as the Stacker Reclaimer Bucket Wheel is only expected to increase. With its proven track record and commitment to innovation, this company is well-positioned to continue providing cutting-edge technology that meets the evolving needs of its customers around the world.

High-quality Hold Down Conveyor Wheels for Improved Stability and Performance

Conveyor Hold Down Wheels: The Backbone of Efficient Material HandlingIn the fast-paced world of material handling, efficiency is key. Companies are constantly searching for ways to streamline their processes and increase productivity. This is where Conveyor Hold Down Wheels play a crucial role. These small yet powerful components are the backbone of efficient material handling, ensuring smooth and reliable transportation of goods across various industries.*** (company name) is a leading manufacturer of Conveyor Hold Down Wheels, with a proven track record of providing top-quality products to their customers. With over 20 years of experience in the industry, they have established themselves as a trusted name in the world of material handling.Conveyor Hold Down Wheels may seem like a minor component in the grand scheme of things, but they play a significant role in ensuring the smooth operation of conveyor systems. These wheels are designed to keep the conveyor belt in place, preventing it from slipping or moving out of alignment during the transportation of goods. This is crucial in preventing costly downtime and ensuring the safe and efficient movement of materials throughout the facility.The key to the success of Conveyor Hold Down Wheels lies in their design and construction. *** (company name) takes great pride in the quality of their products, using only the finest materials and the latest manufacturing techniques to ensure that their Conveyor Hold Down Wheels are built to last. This commitment to quality has earned them a reputation for producing some of the most reliable and durable hold down wheels on the market.One of the standout features of *** (company name)’s Conveyor Hold Down Wheels is their versatility. These wheels are designed to be compatible with a wide range of conveyor systems, making them suitable for use in various industries, including manufacturing, distribution, and logistics. This versatility allows customers to easily integrate these hold down wheels into their existing conveyor systems, providing a seamless and cost-effective solution for improving material handling efficiency.In addition to their standard range of Conveyor Hold Down Wheels, *** (company name) also offers custom solutions to meet the specific needs of their customers. Whether it's a unique size requirement, a specific material handling challenge, or a specialized application, their team of experts can work closely with clients to develop tailored solutions that address their individual needs.Furthermore, *** (company name) is committed to providing exceptional customer service. Their knowledgeable and responsive team is dedicated to helping customers find the right hold down wheel solution for their specific requirements. From initial inquiries to after-sales support, *** (company name) strives to deliver a seamless and hassle-free experience for their customers, further solidifying their reputation as a trusted partner in the material handling industry.As the demand for efficient material handling solutions continues to grow, the importance of reliable conveyor hold down wheels cannot be overstated. With their commitment to quality, versatility, and customer satisfaction, *** (company name) has established itself as a leader in this space. Their Conveyor Hold Down Wheels are the go-to choice for companies looking to optimize their material handling processes, improve productivity, and reduce downtime.In conclusion, Conveyor Hold Down Wheels may seem like a small component, but they play a crucial role in ensuring the efficient and reliable transportation of goods in various industries. For companies looking to improve their material handling processes, partnering with a trusted manufacturer like *** (company name) is the key to success. With their top-quality products, custom solutions, and exceptional customer service, *** (company name) is poised to continue leading the way in the world of conveyor hold down wheels for years to come.

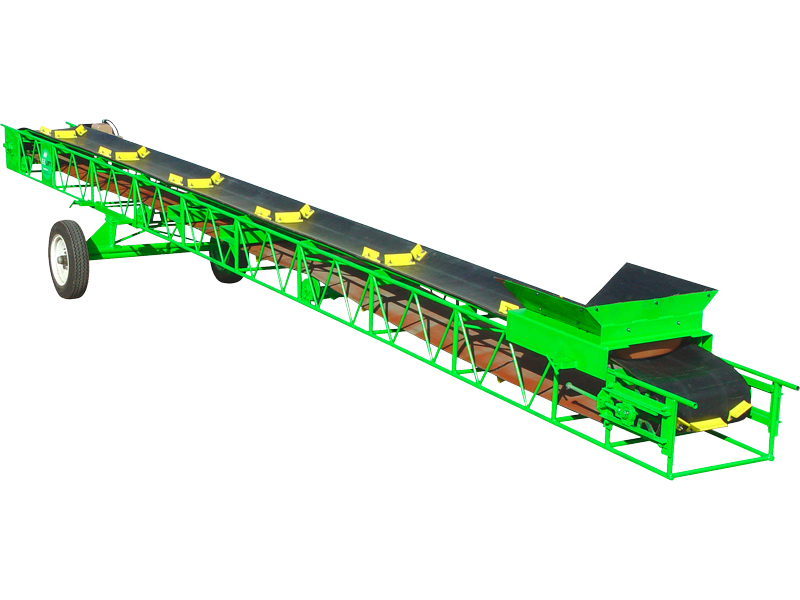

Discover the Advantages and Applications of Outdoor Conveyor Systems

Title: Revolutionizing Outdoor Logistics: Advanced Conveyor Systems Streamline OperationsIntroduction:In a world where efficiency is increasingly sought after, Outdoor Conveyor Systems (OCS) has emerged as a pioneering solution for enhancing logistics operations. Utilizing cutting-edge technology and innovative design, OCS is revolutionizing the way businesses handle material transportation in outdoor environments. With their state-of-the-art systems, OCS is catapulting warehouses, manufacturing plants, and distribution centers into the future of logistics management.I. The Confluence of Efficiency and Adaptability:Outdoor Conveyor Systems' key strength lies in their ability to cater to diverse industrial needs, regardless of the challenging outdoor environment. These systems are intelligently designed to withstand varying weather conditions, terrains, and temperature extremities, ensuring seamless operations in the most demanding of situations.Furthermore, OCS understands the importance of adaptability. Their conveyors can be customized to meet specific requirements, ranging from accommodating heavy loads to handling fragile materials. This adaptability factor provides businesses with the flexibility to optimize their operations and streamline their supply chain management processes.II. Unleashing Automation Potential:The integration of technology and automation has become a defining aspect of the modern industrial landscape. OCS capitalizes on this trend, offering conveyor systems that seamlessly integrate with automated handling systems, further enhancing operational efficiency.These advanced conveyor systems employ robotics, artificial intelligence, and machine learning to efficiently move materials from one point to another, eliminating the need for manual intervention. This automation not only reduces the risk of human errors but also aids in the reduction of labor costs, resulting in improved productivity and profitability for businesses.III. Energy-efficient and Sustainability-focused Design:OCS recognizes the importance of sustainability and environmental consciousness. Their conveyor systems are meticulously designed to minimize energy consumption, employing state-of-the-art energy-efficient motors, sensors, and controls. By optimizing power usage, OCS aims to reduce carbon footprints, contributing to a greener and more sustainable industrial landscape.In addition, OCS prioritizes the use of recyclable and eco-friendly materials in their manufacturing processes. Their commitment to sustainability extends beyond their products to encompass the entire lifecycle, including disposal and recycling protocols.IV. Integration of IoT and Data Analytics:Innovation is at the core of OCS's philosophy. Integrating Internet of Things (IoT) technologies and data analytics, their conveyor systems offer businesses valuable insights into their operations. By harnessing real-time data from sensors embedded in the conveyors, companies can gain a comprehensive understanding of material flow, bottlenecks, and potential optimization areas.This data-driven approach enables businesses to make informed decisions, maximize resource utilization, and implement continuous improvement strategies. The incorporation of IoT and data analytics elevates OCS's conveyor systems to a new level, positioning them as futuristic solutions for efficient outdoor logistics management.V. Industry-specific Applications:Outdoor Conveyor Systems caters to a wide range of industries, including but not limited to:1. Warehousing and Distribution: OCS provides an efficient solution for moving products from receiving to storage areas, enabling efficient order fulfillment and reducing lead times.2. Manufacturing: OCS systems facilitate seamless material flow within manufacturing plants, ensuring uninterrupted production cycles and minimal downtime.3. Mining and Construction: OCS offers robust conveyor systems that can withstand extreme conditions, enabling the safe and efficient movement of materials in heavy industries.Conclusion:Outdoor Conveyor Systems (OCS) has revolutionized the way businesses handle logistics in outdoor environments. By offering adaptable, energy-efficient, and technologically advanced conveyor systems, OCS has become a key player in streamlining supply chain management processes. The integration of automation, IoT, and data analytics not only improves operational efficiency but also provides businesses with valuable insights for continuous improvement. With their focus on sustainability and commitment to customer satisfaction, OCS is driving the outdoor conveyor industry forward, empowering businesses to navigate the challenges of modern logistics with ease.

Innovative Conveyor Belt Cleaner System for Efficient Material Handling

Conveyor Belt Cleaner System Revolutionizes Industrial MaintenanceIn the world of industrial manufacturing and material handling, conveyor belt systems are an essential component for the efficient and seamless flow of goods and materials. However, the proper maintenance of these conveyor belt systems is often overlooked, leading to inefficiencies, downtime, and increased operating costs. In response to this common challenge, a leading company in the field has developed an innovative Conveyor Belt Cleaner System that is revolutionizing the way industrial facilities approach conveyor belt maintenance.Established in 1995, {Company Name} has been at the forefront of developing innovative solutions for bulk material handling. With a strong focus on research and development, the company has continuously pushed the boundaries of traditional conveyor belt technology, striving to improve efficiency, reduce maintenance costs, and enhance worker safety. The result of their commitment to innovation is the revolutionary Conveyor Belt Cleaner System, which has been making waves in the industry due to its advanced design and unparalleled performance.The {Company Name} Conveyor Belt Cleaner System is engineered to address the common issues associated with traditional conveyor belt cleaning methods. Designed to effectively remove carryback, spillage, and dust from the conveyor belt surface, this system ensures a clean and efficient material transfer, ultimately leading to improved productivity and reduced maintenance costs. What sets this system apart from others on the market is its unique combination of high-performance components, including a durable polyurethane blade, a tensioning system, and a corrosion-resistant mainframe.One of the key advantages of the {Company Name} Conveyor Belt Cleaner System is its ability to adapt to a wide range of conveyor belt sizes and applications. Whether it's a heavy-duty mining operation or a food processing facility, this system can be customized to meet the specific needs of any industry. Furthermore, its ease of installation and maintenance makes it a cost-effective solution for businesses looking to streamline their conveyor belt maintenance processes.In addition to its exceptional performance, the {Company Name} Conveyor Belt Cleaner System also prioritizes safety and environmental sustainability. The system is designed to minimize the risk of workplace accidents by effectively containing and controlling carryback, reducing the potential for slip and fall incidents. Moreover, its efficient material removal capabilities contribute to a cleaner and safer working environment, as well as a reduced impact on the surrounding ecosystem.The success of the {Company Name} Conveyor Belt Cleaner System is a testament to the company's dedication to excellence and customer satisfaction. With a team of experienced engineers and technical specialists, {Company Name} provides comprehensive support to its clients, offering expert guidance on system selection, installation, and ongoing maintenance. Their commitment to quality and reliability has earned the trust of prominent industry players, making the {Company Name} Conveyor Belt Cleaner System the top choice for businesses seeking to optimize their conveyor belt maintenance practices.Looking ahead, {Company Name} is committed to furthering the development of innovative solutions that will continue to drive the industry forward. Their ongoing investment in research and development ensures that their products will remain at the forefront of technological advancements, meeting the evolving needs of the industrial sector.In conclusion, the {Company Name} Conveyor Belt Cleaner System represents a significant advancement in conveyor belt maintenance technology. Its ability to enhance efficiency, improve safety, and reduce environmental impact makes it a game-changer for industrial facilities around the world. As {Company Name} continues to lead the way in innovation, it is clear that their commitment to excellence will shape the future of material handling technology.

New Cooling Conveyor Belt Innovation Helps Improve Production Efficiency

[Company Name] Introduces Innovative Cooling Conveyor Belt for Industrial Applications[Company Name], a leading provider of industrial machinery and equipment, has recently introduced an innovative cooling conveyor belt designed to enhance the efficiency and productivity of various industrial processes.The [Company Name] cooling conveyor belt is a state-of-the-art solution that offers reliable and consistent cooling for products as they move along the production line. This advanced system is capable of handling a wide range of products, including food items, pharmaceuticals, and other industrial goods, making it a versatile solution for various manufacturing and processing operations.The cooling conveyor belt is equipped with a series of cooling fans and adjustable speed controls, allowing for precise temperature regulation to meet the specific needs of each production line. This level of customization ensures that products are cooled to the desired temperature, maintaining their quality and integrity throughout the manufacturing process.With the [Company Name] cooling conveyor belt, manufacturers can benefit from improved production efficiency and throughput. The system is designed to optimize the cooling process, reducing the time required for products to reach the desired temperature and allowing for faster throughput and increased productivity.Additionally, the cooling conveyor belt offers a compact and space-saving design, making it an ideal solution for facilities with limited space. Its modular construction allows for easy integration into existing production lines, minimizing downtime and disruption to ongoing operations.Furthermore, the cooling conveyor belt is built with durable and high-quality materials, ensuring long-term reliability and performance. This results in reduced maintenance requirements and lower overall operating costs, providing a cost-effective solution for industrial applications.In addition to its cooling capabilities, the [Company Name] cooling conveyor belt is also equipped with advanced safety features to protect workers and maintain a secure working environment. This includes emergency stop buttons, safety guarding, and other essential safety mechanisms to prevent accidents and ensure compliance with industry regulations.The introduction of the cooling conveyor belt further solidifies [Company Name]'s commitment to providing innovative solutions that address the evolving needs of the industrial sector. The company's extensive experience and expertise in manufacturing and engineering have allowed them to develop a cutting-edge system that delivers unparalleled performance and reliability."We are excited to introduce our new cooling conveyor belt to the market," said the spokesperson for [Company Name]. "This innovative solution is the result of our ongoing dedication to research and development, as well as our commitment to meeting the needs of our customers. We believe that the cooling conveyor belt will provide significant benefits for manufacturers across various industries, helping them optimize their production processes and achieve greater success."[Company Name] has a long-standing reputation for delivering high-quality industrial machinery and equipment, and the introduction of the cooling conveyor belt further strengthens its position as a leading provider of innovative solutions for the industrial sector.Manufacturers and businesses interested in learning more about the [Company Name] cooling conveyor belt and its capabilities are encouraged to contact the company directly or visit their website for additional information and to discuss their specific requirements.

High-Quality Vibrating Conveyor Parts for Industrial Use

Vibrating Conveyor Parts: Keeping the Industry MovingVibrating conveyors are a crucial part of many industries, facilitating the seamless movement of materials throughout the production process. From heavy-duty mining operations to delicate food processing, these conveyors play a vital role in keeping the industry moving.One company that has been at the forefront of manufacturing high-quality vibrating conveyor parts is {}. With a long-standing reputation for excellence in the field of material handling equipment, they have been providing top-of-the-line conveyor parts to a wide range of industries for decades.{} was founded in the early 1980s with a mission to design and manufacture reliable and efficient material handling equipment. Over the years, the company has continued to innovate and expand its product line, offering a comprehensive range of vibrating conveyor parts to meet the diverse needs of their customers.The key to the success of {} lies in their unwavering commitment to quality and innovation. Their team of engineers and designers are constantly striving to improve and optimize their products, ensuring that they are at the cutting edge of industry technology. This dedication to excellence has earned them a strong reputation within the industry, with many customers relying on {} for their material handling needs.One of the hallmarks of {}'s products is their durability and reliability. The vibrating conveyor parts manufactured by {} are built to withstand the rigors of industrial use, ensuring that they can continue to operate at peak performance even in the most demanding environments. This reliability is crucial for businesses that rely on their material handling equipment to keep their operations running smoothly.In addition to their emphasis on quality, {} is also known for their exceptional customer service. Their team is dedicated to providing the highest level of support to their clients, offering expert guidance and assistance throughout the purchasing and installation process. This commitment to customer satisfaction has helped {} build strong, lasting relationships with their clients, many of whom return to them for all their material handling equipment needs.One of the key products that {} offers is their range of vibrating conveyor parts. These parts are designed to optimize the performance of vibrating conveyors, ensuring smooth and efficient material handling. From motorized vibrating drives to flexible support springs, {} offers a comprehensive selection of parts to suit a variety of conveyor systems.The vibrating conveyor parts manufactured by {} are designed to meet the highest standards of quality and performance. Each part is meticulously crafted using the finest materials and cutting-edge manufacturing techniques, ensuring that they are built to last. Whether it's a replacement part for an existing conveyor or a custom-designed component for a new system, {} has the expertise and capability to meet their customers' needs.With a focus on innovation and customer satisfaction, {} is well-positioned to meet the evolving needs of the material handling industry. As technology and processes continue to advance, the demand for reliable and efficient conveyor systems will only grow, and {} is poised to lead the way with their top-of-the-line vibrating conveyor parts.As the industry continues to evolve, {} remains committed to providing the highest quality products and the best possible service to their customers. With a strong reputation for excellence and a track record of success, {} is sure to remain a leader in the field of material handling equipment for many years to come. Whether it's a small-scale operation or a large industrial facility, businesses can rely on {} to keep them moving forward.

The Importance of Bend Pulleys and Snub Pulleys in Conveyor Systems

In the world of manufacturing and material handling, the importance of efficient and reliable conveyor systems cannot be overstated. These systems are responsible for transporting a wide range of materials and products, and their smooth and continuous operation is crucial for the success of many industries. Among the components that play a key role in the functioning of conveyor systems are bend pulleys and snub pulleys.Bend pulleys are an essential part of conveyor systems, as they are used to change the direction of the belt in a conveyor system. They are typically installed at the tail end of the conveyor and are designed to guide the belt around a curve. This helps to prevent the belt from coming off the conveyor and ensures that the material being transported is properly guided along its intended path.Snub pulleys, on the other hand, are used to increase the wrap angle of the belt around the drive pulley. This helps to increase the traction between the belt and the drive pulley, which in turn improves the efficiency and performance of the conveyor system. By increasing the amount of surface in contact with the belt, snub pulleys help to reduce slipping and improve the overall operation of the conveyor.Both bend pulleys and snub pulleys are crucial components in ensuring the smooth and reliable operation of conveyor systems in a wide range of industries, including mining, automotive, food processing, and logistics, among others. As such, the quality and reliability of these components are of paramount importance to the companies that rely on conveyor systems for their operations.One company that has established itself as a leading provider of high-quality bend pulleys and snub pulleys is {}. With a strong focus on engineering excellence and attention to detail, {} has earned a reputation for delivering conveyor components that are durable, efficient, and built to last. The company's bend pulleys and snub pulleys are designed to meet the specific needs of each customer, and they are engineered to withstand the demands of heavy-duty industrial applications.{} has a comprehensive range of bend pulleys and snub pulleys to suit a variety of conveyor systems, including standard duty, medium duty, and heavy-duty applications. The company's bend pulleys are available in a range of sizes and configurations, and they can be customized to meet the unique requirements of each customer's conveyor system. Similarly, {}'s snub pulleys are designed to provide optimal performance and reliability, and they are built to withstand the rigors of continuous operation in demanding industrial environments.In addition to offering high-quality bend pulleys and snub pulleys, {} also provides comprehensive support and technical assistance to its customers. The company's team of engineers and technical experts work closely with customers to understand their specific needs and to provide solutions that are tailored to their requirements. Whether it's advising on the selection of the right pulley for a particular application or providing assistance with installation and maintenance, {} is committed to delivering an exceptional customer experience.With a strong track record of delivering reliable and high-performance conveyor components, {} has become a trusted partner for companies across a wide range of industries. The company's dedication to quality, innovation, and customer satisfaction has set it apart as a leading provider of bend pulleys and snub pulleys, and it continues to be a preferred choice for businesses that rely on conveyor systems for their operations.As the demand for efficient and reliable conveyor systems continues to grow, the role of bend pulleys and snub pulleys in ensuring smooth and reliable operation will only become more crucial. With its dedication to excellence and commitment to customer satisfaction, {} is well-positioned to meet the evolving needs of the industry and to continue delivering high-quality conveyor components that drive success for its customers.

Ultimate Guide to Roller Conveyor Guide Rails - Your Complete Resource

Title: Enhancing Efficiency and Safety in Material Transportation: Introducing Roller Conveyor Guide RailsIntroduction:In today's dynamic industrial landscape, the need for efficient and safe material transportation is paramount. Recognizing this need, [Company Name] is proud to introduce its state-of-the-art Roller Conveyor Guide Rails. With a commitment to innovation and excellence, [Company Name] strives to revolutionize the way industries handle material logistics, offering a comprehensive solution that enhances productivity, maximizes floor space utilization, and ensures the safety of workers.Body:1. Understanding the Importance of Roller Conveyor Guide Rails: Roller Conveyor Guide Rails are an integral part of a conveyor system, guiding products along their intended path and preventing them from straying off course. Efficient transportation of goods hinges on the reliability, versatility, and stability of these guide rails. By implementing Roller Conveyor Guide Rails, companies across various industries can significantly streamline their material handling processes, thereby increasing output and reducing downtime.2. Unveiling the Cutting-Edge Features of [Company Name]'s Roller Conveyor Guide Rails: [Company Name]'s Roller Conveyor Guide Rails have been meticulously designed to meet and exceed the industry's expectations. These guide rails offer several notable features: a. Durability and Longevity: Crafted from high-quality materials, including robust stainless steel and impact-resistant polymers, our guide rails ensure longevity, withstanding the rigors of demanding industrial environments. b. Easy Installation and Maintenance: The roller conveyor guide rails are designed for hassle-free installation and maintenance, reducing downtime and operational disruptions significantly. c. Customization Options: At [Company Name], we understand that different industries have specific requirements. Therefore, our guide rails can be customized to meet an array of operational needs, from adjusting height and angle to accommodating various product dimensions. d. Intelligent Design for Optimum Performance: [Company Name]'s Roller Conveyor Guide Rails are engineered with precision, offering smoother transition and minimum friction, leading to improved transport efficiency.3. Advantages of Roller Conveyor Guide Rails: Now, let's explore some of the noteworthy benefits that our guide rails offer: a. Enhanced Operational Efficiency: By ensuring a consistent and controlled flow of materials, our guide rails minimize bottlenecks and optimize overall productivity. Material handling becomes more efficient, facilitating quicker loading and unloading processes. b. Space Utilization: With well-designed guide rails, companies can effectively utilize their existing floor space, eliminating the need for unnecessary expansions. This advantage translates into cost savings and increased operational efficiency. c. Worker Safety: Safety is a top priority for any industry. Roller Conveyor Guide Rails maintain accurate alignment of materials during transportation, reducing the risk of accidents or injuries caused by product instability. d. Versatility: [Company Name]'s Roller Conveyor Guide Rails can be utilized across a wide range of industries and applications, from manufacturing and logistics to food processing and pharmaceuticals. This versatility makes them an invaluable asset for businesses of all sizes.4. Successful Implementation Case Studies: [Company Name] takes pride in its numerous successful implementations of Roller Conveyor Guide Rails. Several notable industrial giants have witnessed the transformative impact of our guide rails in their operations, experiencing increased efficiency, reduced costs, and enhanced worker safety. The testimonials of our satisfied clients serve as a testament to the reliability and effectiveness of our guide rails.Conclusion:In a rapidly evolving industrial landscape, the importance of efficient and safe material transportation cannot be stressed enough. [Company Name]'s Roller Conveyor Guide Rails provide a comprehensive solution for companies seeking to optimize their material handling processes, reduce operational costs, and improve worker safety. With cutting-edge features, customizable options, and a track record of successful implementations, [Company Name] is proud to introduce a game-changing solution that caters to the diverse needs of various industries. By investing in Roller Conveyor Guide Rails, companies can unlock their true potential by enhancing efficiency while ensuring worker well-being.