Essential Parts of a Belt Conveyor System

By:Admin

Belt Conveyor System Parts are essential components of conveyor systems, designed to move products along the conveyor line. These parts include roller, idler, drive pulley, bend pulley, impact roller, and other accessories. The Belt Conveyor System Parts market is expected to witness significant growth in the coming years, driven by the increasing demand for automated material handling systems in various industries such as manufacturing, logistics, and mining.

The Belt Conveyor System Parts Market report covers a detailed analysis of the key players in the industry, including their company profiles, product portfolio, capacity, production, and revenue. The report also provides a comprehensive analysis of the market competition, with the top manufacturers dominating the market share.

One of the leading players in the Belt Conveyor System Parts industry is {}, a renowned company specializing in the design, manufacturing, and installation of conveyor systems and components. Established in {}, {} has been at the forefront of innovation in the material handling industry, providing high-quality products and solutions to customers worldwide.

{}’s product line includes a wide range of Belt Conveyor System Parts, including rollers, idlers, pulleys, and other accessories. With a focus on quality and reliability, {} has established itself as a trusted partner for companies looking to enhance their material handling processes. The company's in-house manufacturing facilities, coupled with a dedicated R&D team, enable {} to develop innovative solutions that meet the ever-evolving needs of the industry.

In addition to its product offerings, {} also provides comprehensive services such as installation, maintenance, and repair of conveyor systems. With a team of experienced technicians and engineers, {} ensures the smooth operation of their customers' conveyor systems, minimizing downtime and maximizing productivity.

As the Belt Conveyor System Parts market continues to grow, {} remains committed to providing cutting-edge solutions that drive efficiency and cost savings for its customers. With a strong focus on sustainability and environmental responsibility, {} incorporates eco-friendly materials and processes into its product development, aligning with the global trends towards green and sustainable manufacturing practices.

In conclusion, the Belt Conveyor System Parts Market report provides a comprehensive overview of the industry, including market trends, drivers, challenges, and opportunities. With the increasing adoption of automated material handling systems across various industries, the demand for Belt Conveyor System Parts is expected to soar in the coming years, presenting lucrative opportunities for manufacturers and suppliers in the market. As a leading player in the industry, {} is well-positioned to capitalize on this growth and continue to deliver exceptional value to its customers.

Company News & Blog

Innovative Roofing Conveyor Belt Offers Efficient Solution for Construction Projects

The roofing industry is constantly evolving, with new technologies and tools emerging to make the job more efficient and effective. One such innovation is the use of a roofing conveyor belt, which has been revolutionizing the way roofing materials are transported and installed on construction sites.One company that has been at the forefront of this technological advancement is {}. {} is a leading provider of construction equipment and tools, and they have developed a state-of-the-art roofing conveyor belt that is designed to streamline the roofing process and make it easier for contractors to get the job done.The {} roofing conveyor belt is a game-changer for roofing contractors, as it eliminates the need for manual lifting and carrying of heavy materials. This not only reduces the risk of injury for workers, but also allows for a more efficient and productive workflow on the job site. The conveyor belt is designed to easily transport heavy materials such as shingles, tiles, and other roofing components, allowing for quick and easy installation.The {} roofing conveyor belt is also designed with versatility in mind, as it can be easily maneuvered and adjusted to fit the specific needs of different job sites. This means that contractors can use the conveyor belt for a wide range of roofing projects, from residential homes to large commercial buildings. With its ability to handle various types of roofing materials and navigate different terrains, the {} roofing conveyor belt has become an essential tool for any roofing contractor looking to optimize their operations.In addition to its practical benefits, the {} roofing conveyor belt also offers a cost-effective solution for contractors. By reducing the time and labor required for roofing installations, the conveyor belt helps to lower overall project costs and increase profitability for contractors. This makes it a highly valuable investment for any roofing business, as it can ultimately lead to greater efficiency and higher returns on projects.Furthermore, the {} roofing conveyor belt is backed by the company's commitment to quality and reliability. As a trusted provider of construction equipment, {} has a reputation for delivering durable and high-performing products that meet the needs of contractors in the field. The conveyor belt is built to withstand the rigors of roofing work, with a rugged design and durable construction that ensures long-lasting performance in any environment.With its innovative design, versatility, and cost-saving benefits, the {} roofing conveyor belt has quickly become a must-have tool for roofing contractors across the industry. As the demand for efficient and productive roofing solutions continues to grow, this innovative technology is poised to play a pivotal role in shaping the future of the roofing industry.In conclusion, the {} roofing conveyor belt is a testament to the ongoing advancements in construction technology, and it is set to transform the way roofing projects are approached and executed. With its practical benefits, cost-effective advantages, and reliable performance, this innovative tool has become an indispensable asset for contractors seeking to enhance their operations and deliver superior results for their clients. As the roofing industry continues to evolve, the {} roofing conveyor belt stands as a shining example of the innovation and progress that are driving the success of modern construction practices.

New Device Allows for Efficient Conveyor Belt Tracking

Belt Trackers Conveyor introduces a revolutionary product that will change the material handling industry. The company has developed a state-of-the-art conveyor system that is designed to optimize performance, increase productivity and reduce operational costs. This new conveyor system is specifically aimed at helping businesses streamline their production and improve their bottom line.The Belt Trackers Conveyor has been developed by a team of highly experienced engineers who took a fresh approach to material handling. The team realized that the traditional conveyor systems available in the market today are not able to keep up with the changing demands of modern-day production. These outdated systems are often prone to breakdowns, require costly maintenance, and are not energy-efficient.The Belt Trackers Conveyor is designed to overcome these challenges. It incorporates cutting-edge technology that enables it to adjust to any changes or fluctuations in the conveyor belt. This means that the system is self-correcting and can maintain its alignment regardless of the operating conditions. This eliminates the need for constant manual adjustments, improving efficiency and reducing wear and tear on the equipment.The Belt Trackers Conveyor is also equipped with a range of advanced sensors that monitor the performance of the system and alert the operators if any issues arise. This proactive approach to maintenance helps to reduce downtime, increase productivity, and save businesses valuable time and money.One of the most significant benefits of the Belt Trackers Conveyor is its energy efficiency. The system is designed to operate at a low power consumption rate, thereby reducing energy costs and carbon footprint. This energy-efficient feature is a significant advantage for businesses that are looking to reduce their environmental impact and improve sustainability.Belt Trackers Conveyor is confident that this innovative product will revolutionize the material handling industry. They pride themselves on providing cutting-edge solutions designed to meet the unique needs of businesses of all sizes and industries. Belt Trackers Conveyor is committed to delivering the highest quality products, backed by exceptional customer service, to ensure complete customer satisfaction.The company's dedication to research and development has made them an industry leader in material handling systems. They have a proven track record of delivering the most advanced technology in the market, and the Belt Trackers Conveyor is no exception. This product combines the latest in engineering, software, and automation to create a powerhouse conveyor system that will take material handling to the next level.The Belt Trackers Conveyor is a versatile system that can be used in a wide range of industries, including food and beverage, pharmaceuticals, automotive, and logistics. Its ability to handle different types of materials, from delicate to heavy-duty, makes it an ideal choice for businesses that require flexibility and adaptability in their operations.Belt Trackers Conveyor is committed to providing its customers with the most innovative solutions in material handling. They believe in building long-term relationships with their clients and providing ongoing support to help them achieve their operational goals. The Belt Trackers Conveyor is an excellent example of their commitment to delivering high-quality products that exceed customer expectations.In conclusion, the Belt Trackers Conveyor is a game-changer in the material handling industry. Its advanced technology, energy efficiency, and versatility make it an ideal choice for businesses that are seeking to improve their operational performance and reduce costs. Belt Trackers Conveyor is proud to be at the forefront of this innovation, and they are confident that their product will revolutionize the way businesses handle their materials. Now that the Belt Trackers Conveyor has been introduced to the market, it is only a matter of time before it becomes the industry standard.

Essential Guide to Return Idler Rollers: Types, Maintenance, and Installation

Return Idler Roller plays a crucial role in the conveyor system, ensuring the smooth and efficient transportation of materials. With the continuous advancement of technology, the demand for high-quality return idler rollers has been on the rise. As a leading manufacturer and supplier in the industry, {Company Name} is dedicated to providing top-notch return idler rollers to meet the growing needs of various businesses.{Company Name} has been at the forefront of developing and producing return idler rollers that are not only durable and reliable but also innovative and cost-effective. With a strong focus on research and development, the company has been able to continually improve its products to meet the ever-changing demands of the market. The return idler rollers offered by {Company Name} are designed to minimize maintenance and maximize the efficiency of conveyor systems in a wide range of industries.One of the key features of the return idler rollers produced by {Company Name} is their exceptional durability. The rollers are constructed using high-quality materials that are able to withstand the wear and tear of continuous use, ensuring a longer lifespan and reduced downtime for businesses. Additionally, {Company Name} also offers customizable options for return idler rollers, allowing businesses to tailor the products to their specific needs and requirements.In addition to their durability, the return idler rollers from {Company Name} are also designed to optimize the performance of conveyor systems. With smooth rotation and minimal vibration, the rollers help to prevent material buildup and reduce the risk of damage to the conveyor belt. This not only increases the overall efficiency of the system but also helps to lower maintenance costs for businesses.{Company Name} takes pride in its commitment to quality and customer satisfaction. The company ensures that each return idler roller is thoroughly tested to meet the highest standards before being delivered to customers. With a team of experienced engineers and technicians, {Company Name} also provides comprehensive technical support and guidance to help businesses select the most suitable return idler rollers for their specific applications.Furthermore, {Company Name} is dedicated to environmental sustainability and ensures that its manufacturing processes adhere to strict environmental standards. The company strives to minimize its carbon footprint and reduce waste production, making it a responsible and ethical choice for businesses looking to partner with environmentally conscious suppliers.With a strong global presence, {Company Name} has established itself as a trusted and reliable source for return idler rollers. The company serves a diverse customer base in various industries, including mining, construction, agriculture, and manufacturing. {Company Name} is committed to forging long-term partnerships with its clients, providing ongoing support and collaborating on tailored solutions to meet their evolving needs.As the demand for return idler rollers continues to grow, {Company Name} remains at the forefront of the industry, offering innovative and high-quality products that set the standard for conveyor system efficiency and reliability. With a solid track record of success and a dedication to excellence, {Company Name} is poised to continue its leadership in the market for return idler rollers, providing businesses with the tools they need to optimize their operations and drive success.

Essential Spare Parts for Efficient Chain Conveyors - A Comprehensive Guide

Chain Conveyor Spare Parts, based in the United States, is a top global company that specializes in providing high-quality conveyor spare parts. The company boasts over 50 years of experience in the industry and has successfully expanded its services worldwide. Chain Conveyor Spare Parts prides itself on its unparalleled level of customer satisfaction, quality, and innovation. The expert team at Chain Conveyor Spare Parts continuously strives to deliver unique and innovative solutions to clients in various sectors, including automotive, food, packaging, beverage, petrochemical, and many more.Chain Conveyor Spare Parts is renowned for offering a comprehensive range of conveyor spare parts, including stainless steel chains, conveyor sprockets, wear strips, conveyor belts, drive chains, conveyor rollers, and much more. Moreover, the company also provides customized conveyor solutions, from conveyor design, fabrication, installation, testing, and maintenance. Indeed, this has contributed to the company's reputation for providing exceptional customer service, making it highly preferred by its esteemed clients.The conveyor spare parts provided by the company are of exceptional quality. The spare parts undergo rigorous testing and quality assurance checks before being delivered to the client. Chain Conveyor Spare Parts understands the importance of reliability, performance, and efficiency of conveyor systems that make up a production line. The company ensures only top-tier and high-performance spare parts are provided to clients, which significantly reduces downtime, maintenance costs, and enhances overall productivity.The company also recognizes the impact of technological advancements and innovations in conveyor systems. The team of experts a Chain Conveyor Spare Parts is always at the forefront in the integration of the latest technologies, such as automation, robotics, and artificial intelligence, to ensure the improvement of the spare parts and conveyor systems. Consequently, clients of Chain Conveyor Spare Parts gain an added value by receiving cutting-edge conveyor solutions that ultimately results in faster production, increased efficiency, and cost savings.Moreover, the company has a global reach, providing tailor-made conveyor solutions to business and industries across the world. Chain Conveyor Spare Parts' mission is to supply high-quality conveyor spare parts, support, and guidance, regardless of customers' location. The company has achieved this by establishing a vast network of carefully selected partners and distributors worldwide. It has also established several offices and warehouses in strategic locations in Europe, Asia, and the Americas.In conclusion, Chain Conveyor Spare Parts is the go-to company for businesses, and industries seeking to rely on high-quality conveyor spare parts and solutions. The company's experience, combined with customer-centric leadership and innovative technologies, has propelled it to the top of the conveyor solutions industry. Chain Conveyor Spare Parts' global presence and established network of partners worldwide affirm its commitment to providing superior and reliable services. The company is committed to delivering exceptional customer service, top-quality spare parts, and innovative solutions that optimize productivity, efficiency, and profitability for its clients. Ultimately, Chain Conveyor Spare Parts aims to help its clients achieve their business goals and help them grow.

Industrial Conveyor Chains: Everything You Need to Know

Leading Conveyor Chain Manufacturer Introduces X678 Conveyor Chain for Improved EfficiencyAs the world continues to evolve and advance, industries are constantly seeking innovative solutions to improve their production processes. In line with this, one of the leading conveyor chain manufacturers, {Company Name}, has introduced the X678 Conveyor Chain, a game-changing product designed to enhance the efficiency and reliability of conveyor systems in various industries.{Company Name} has a long-standing reputation for providing high-quality conveyor chains that meet the specific needs of their customers. With a strong focus on innovation and continuous improvement, the company has earned the trust and loyalty of clients across the globe. The introduction of the X678 Conveyor Chain is part of {Company Name}'s commitment to delivering cutting-edge solutions that drive productivity and performance for their customers.The X678 Conveyor Chain is built to withstand the demanding conditions of modern industrial operations. It is constructed using premium quality materials and state-of-the-art manufacturing processes, ensuring durability and longevity even in the most challenging environments. The chain's design incorporates advanced engineering features that optimize its performance, including precision-machined components and a superior surface finish for reduced friction and wear.One of the key benefits of the X678 Conveyor Chain is its ability to handle heavy loads with ease, making it an ideal choice for industries such as mining, automotive, steel, and heavy manufacturing. With its high tensile strength and exceptional resistance to fatigue, the chain can reliably support and transport heavy materials, contributing to smoother and more efficient production processes.In addition to its robustness, the X678 Conveyor Chain is engineered for minimal maintenance, reducing downtime and operational costs for businesses. Its design includes self-lubricating features and superior wear resistance, ensuring reliable performance over extended periods without the need for frequent repairs or replacements. This translates to significant savings for companies that rely on conveyor systems for their daily operations.Another standout feature of the X678 Conveyor Chain is its versatility, offering compatibility with a wide range of conveyor systems and applications. Whether it's handling bulk materials, heavy-duty processing, or precision conveying, the chain's performance remains consistent and reliable. This adaptability makes it a valuable asset for businesses with diverse operational requirements, providing a seamless and dependable material handling solution.To further support its customers, {Company Name} offers comprehensive technical support and aftermarket services for the X678 Conveyor Chain. Their team of experienced engineers and technicians are readily available to assist with installation, maintenance, and troubleshooting, ensuring that customers get the most out of their investment in this innovative product. This commitment to customer satisfaction is a cornerstone of {Company Name}'s ethos, solidifying its position as a trusted partner in the industry.The introduction of the X678 Conveyor Chain marks a significant milestone for {Company Name}, demonstrating their dedication to driving progress and efficiency for their clients. With its exceptional performance capabilities, rugged durability, and versatile applications, the chain sets a new standard for conveyor system reliability and productivity. As industries continue to evolve and demand higher standards for their operations, the X678 Conveyor Chain positions {Company Name} at the forefront of delivering innovative solutions that meet and exceed these expectations.In conclusion, the X678 Conveyor Chain from {Company Name} represents a leap forward in material handling technology, offering a superior solution for industries seeking to enhance their conveyor systems. With its robust construction, minimal maintenance requirements, and versatile performance, the chain is poised to make a significant impact on the efficiency and reliability of conveyor operations across various sectors. As businesses strive to optimize their production processes and stay competitive in a dynamic market, the X678 Conveyor Chain stands out as a valuable asset for driving progress and success.

Discover Top-Quality Conveyor Accessories for Efficient Operations

[Company Introduction - Revamp Industries]Revamp Industries is a leading player in the manufacturing and supplying of conveyor accessories globally. With a rich history spanning over two decades, the company has gained a commendable reputation for providing high-quality products and exceptional customer service.Founded in [year], Revamp Industries has grown steadily to become a trusted name in the conveyor systems industry. Our commitment to innovation and continuous improvement has allowed us to develop an extensive range of conveyor accessories that cater to various industries and applications.At Revamp Industries, our skilled team of engineers and technicians work diligently to design and manufacture conveyor accessories that meet the highest standards of quality and reliability. We understand the critical role these components play in ensuring the smooth and efficient operation of conveyor systems, and therefore, we leave no stone unturned in delivering superior products.Our product portfolio includes a wide array of conveyor accessories, including but not limited to rollers, pulleys, belt cleaners, idlers, and impact beds. Each product is manufactured using state-of-the-art technology and undergoes rigorous testing to ensure its durability and performance. We also offer customization options to meet specific customer requirements, ensuring the perfect fit for any conveyor system.Revamp Industries takes great pride in its ability to provide exceptional customer service. Our team of experts is always available to offer technical support, assist with product selection, and provide prompt responses to any queries or concerns. We strive to build long-lasting relationships with our customers, and their satisfaction is our topmost priority.As a responsible corporate citizen, Revamp Industries is committed to sustainable manufacturing practices. We understand the importance of minimizing our environmental impact, and therefore, we continually invest in eco-friendly technologies and processes. Our commitment to sustainability extends to our supply chain as well, ensuring that the materials used in our products are ethically sourced and environmentally friendly.Our dedication to excellence has earned us recognition and approvals from leading industry bodies and organizations. We are proud to have certifications such as ISO 9001 and OHSAS 18001, which validate our commitment to quality management systems and occupational health and safety standards, respectively.In an industry that is constantly evolving, Revamp Industries stays ahead of the curve by investing in research and development. We strive to bring the latest advancements in conveyor technology to our customers, enabling them to enhance productivity, reduce downtime, and optimize their operations.[News Content - Conveyor Accessories]Revamp Industries, a globally recognized name in the conveyor systems industry, continues to impress with their range of conveyor accessories that ensure smooth and efficient operations. The company, with its unwavering commitment to quality, offers a diverse portfolio of products that cater to various industries and applications.One of the key offerings from Revamp Industries is their line of high-quality rollers. These rollers are designed with precision and manufactured to withstand the most demanding environments. The company's rollers are known for their durability, reliability, and low maintenance, making them the preferred choice for many conveyor systems.In addition to rollers, Revamp Industries also provides top-of-the-line pulleys. These pulleys are engineered to deliver optimal performance and longevity, ensuring consistent and trouble-free operation. The company's expertise in pulley design and manufacturing has made them a trusted partner for businesses looking to enhance their conveyor systems.To complement their rollers and pulleys, Revamp Industries offers a range of belt cleaners that effectively remove material carryback, thereby improving belt performance and reducing maintenance costs. These belt cleaners are designed for easy installation and require minimal adjustments, optimizing efficiency and productivity.Revamp Industries' idlers are another standout product in their conveyor accessory lineup. These idlers are designed to minimize belt sag and improve overall belt tracking, resulting in increased conveyor efficiency. The company's idlers are rigorously tested to ensure they meet industry standards and withstand the most demanding applications.For industries that require additional support for heavy loads and impact resistance, Revamp Industries' impact beds are the perfect solution. These impact beds provide cushioning and protection to the conveyor belt, reducing the risk of damage and extending its lifespan. The company's impact beds are engineered to absorb shock and resist abrasion, ensuring uninterrupted operations even in the harshest conditions.With a commitment to sustainability, Revamp Industries ensures that all their conveyor accessories are manufactured using eco-friendly materials and processes. As companies worldwide strive to minimize their environmental footprint, partnering with a responsible and ethical supplier like Revamp Industries is a step towards a greener future.Revamp Industries' passion for innovation and dedication to customer satisfaction is what sets them apart in the conveyor systems industry. The company's vast range of conveyor accessories, combined with their exceptional customer service, makes them the preferred choice for businesses seeking reliable and high-performing solutions.In conclusion, Revamp Industries continues to revolutionize the conveyor systems industry with their range of conveyor accessories. Their commitment to quality, sustainability, and customer satisfaction has earned them a stellar reputation globally. As the industry evolves, Revamp Industries remains at the forefront, providing innovative solutions that enable businesses to optimize their operations and stay ahead of the competition.

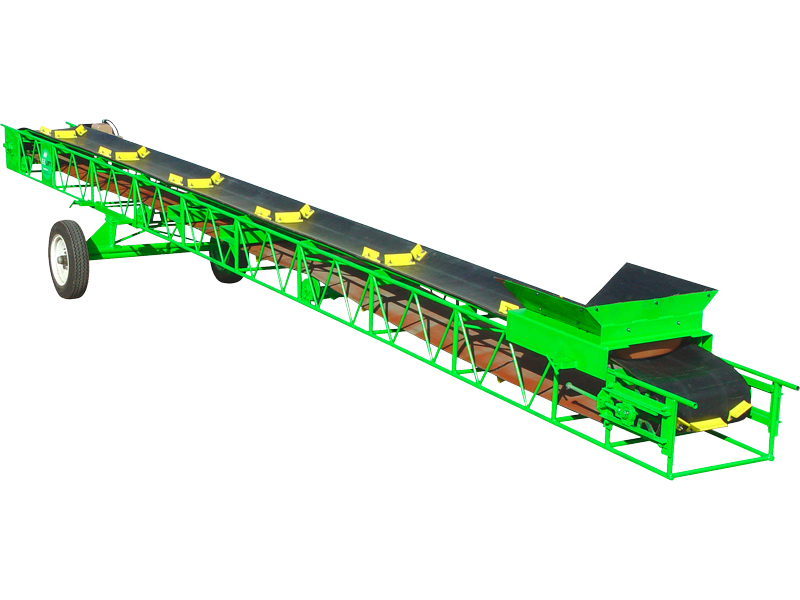

Highly efficient incline conveyor with cleated belt for various industries

Cleated Incline Conveyor Revolutionizes Material HandlingIn the fast-paced world of manufacturing and logistics, efficiency is key. Whether it's moving raw materials through a production line or transferring finished products to the shipping department, having the right equipment can make all the difference. That's why the introduction of the Cleated Incline Conveyor by [Company Name], a leader in material handling solutions, has sent ripples of excitement through the industry.The Cleated Incline Conveyor is a game changer for businesses looking to streamline their material handling processes. With its innovative design and advanced functionality, this conveyor is able to handle a wide range of materials, from small components to large, heavy items. Its cleated belt and adjustable incline angle make it versatile enough to accommodate the unique needs of different industries, including automotive, food and beverage, and pharmaceuticals.What sets the Cleated Incline Conveyor apart from other similar products on the market is its reliability and durability. [Company Name] has a reputation for producing high-quality equipment that stands the test of time, and the Cleated Incline Conveyor is no exception. It is built to withstand the rigors of industrial use, with heavy-duty construction and a low-maintenance design that minimizes downtime and reduces the overall cost of ownership.In addition to its robust build, the Cleated Incline Conveyor also boasts a range of features that make it easy to use and maintain. The user-friendly control panel allows operators to quickly adjust the speed and incline of the conveyor, while the self-cleaning design helps to prevent build-up and minimize the risk of jams. These features not only enhance the overall efficiency of the conveyor but also make it safer for workers to operate.One of the key advantages of the Cleated Incline Conveyor is its ability to improve the overall productivity of a facility. By automating the movement of materials, businesses can reduce the need for manual handling, which in turn minimizes the risk of injury and worker fatigue. This not only benefits the well-being of employees but also contributes to a more efficient and agile operation.[Company Name] is proud to offer the Cleated Incline Conveyor as part of its comprehensive range of material handling solutions. With a focus on innovation and customer satisfaction, the company has become a trusted partner for businesses looking to optimize their processes and improve their bottom line. Its team of experienced engineers and industry experts are dedicated to providing tailored solutions that meet the unique needs of each customer, ensuring they get the best possible return on their investment.The addition of the Cleated Incline Conveyor to the [Company Name] product lineup is a testament to its ongoing commitment to excellence and continuous improvement. By staying at the forefront of technological advancements and market trends, the company is able to deliver cutting-edge solutions that enable its customers to stay ahead of the competition.Looking ahead, [Company Name] is poised to continue pushing the boundaries of material handling technology, with a focus on innovation, reliability, and customer satisfaction. The introduction of the Cleated Incline Conveyor is just the beginning of what promises to be an exciting journey for the company and its customers. With a solid track record and a clear vision for the future, [Company Name] is well-positioned to lead the way in the world of material handling for years to come.

New Conveyor System for Quarries: Improved Efficiency and Productivity

The quarry conveyor is a crucial piece of equipment for the mining and construction industry, as it efficiently transports materials from one place to another, making the process of excavating and processing materials much easier and more efficient. With the increasing demand for quarried materials such as gravel, sand, and stone, the quarry conveyor plays a vital role in ensuring that these materials are transported and processed in a timely and efficient manner.One of the leading companies in the development and manufacturing of quarry conveyors is {}. With over 20 years of experience in the industry, the company has become known for its innovative and reliable conveyor systems that are designed to meet the specific needs of the mining and construction sector. The company's range of conveyor systems includes belt conveyors, screw conveyors, and chain conveyors, all of which are designed to handle a wide variety of materials and operating conditions.In addition to manufacturing conveyor systems, {} also provides comprehensive installation, maintenance, and repair services to ensure that their customers' conveyor systems are always operating at their best. This dedication to customer service has helped {} build a strong reputation in the industry, with many companies relying on their expertise to keep their operations running smoothly.One of the key factors that set {} apart from other conveyor manufacturers is their commitment to innovation and continuous improvement. The company invests heavily in research and development to design and engineer conveyor systems that are more efficient, durable, and environmentally friendly. This commitment to innovation has led to the development of conveyor systems that are able to handle heavier loads, operate at higher speeds, and reduce energy consumption, making them an ideal choice for modern quarry operations.In addition to their focus on innovation, {} is also dedicated to ensuring the quality and reliability of their conveyor systems. Each system is manufactured using high-quality materials and components, and undergoes rigorous testing and quality control processes to ensure that it meets the highest industry standards. This commitment to quality has earned {} the trust and confidence of many mining and construction companies, who rely on their conveyor systems to keep their operations running smoothly.With the increasing demand for quarried materials, the role of the quarry conveyor in the mining and construction industry is only expected to grow. As such, companies like {} will continue to play a critical role in providing conveyor systems that are able to meet the evolving needs of the industry. By incorporating innovation, quality, and reliability into their conveyor systems, {} is well-positioned to remain a leader in the development and manufacturing of quarry conveyors for many years to come. Their dedication to customer service and commitment to excellence make them a valuable partner for companies in need of reliable and efficient conveyor systems for their quarry operations.

High-quality Conveyor Belts: Essential Components for Scrapers

Title: Revolutionary Conveyor Belts Enhance Industrial Efficiency and ProductivityIntroduction:[Company Name], a leading provider of innovative industrial equipment, has recently unveiled their advanced line of scrapers conveyor belts. These cutting-edge conveyor belts offer remarkable efficiency, durability, and versatility, aimed at revolutionizing the industrial sector. With their commitment to groundbreaking technology and customer satisfaction, [Company Name] is set to reshape the conveyor belt industry.Section 1: Understanding the Importance of Conveyor BeltsThe use of conveyor belts in various industries, such as mining, manufacturing, and logistics, has become integral for streamlining operations and ensuring smooth material handling processes. [Company Name] recognizes this significance and has dedicated years of research and development to create conveyor belts that redefine industry standards.Section 2: Introducing the Scrapers Conveyor Belt RangeWith its latest offering of scrapers conveyor belts, [Company Name] is empowering businesses with a solution that optimizes efficiency while minimizing downtime. These innovative belts are designed to scrape off stubborn materials that accumulate on the surface, preventing unnecessary disruptions and ensuring consistent workflow.Section 3: Unparalleled Efficiency and DurabilityThe scrapers conveyor belts from [Company Name] are designed using high-quality materials that are resistant to wear, tear, and corrosion. The integration of cutting-edge technology enables these belts to withstand heavy loads, extreme temperatures, and abrasive materials, resulting in extended operational life and reduced maintenance costs.Section 4: Versatile ApplicationsThese conveyor belts are engineered to handle a wide range of materials, making them suitable for diverse industries. The adaptable design facilitates the transportation of coal, minerals, ores, aggregates, and various other bulk materials with utmost ease. Whether it's a coal mine or a manufacturing plant, [Company Name]'s conveyor belts provide seamless and efficient material handling solutions.Section 5: Safety Measures and Environmental Considerations[Company Name] prioritizes the safety of both operators and the environment. The scrapers conveyor belts are equipped with safety features such as emergency stop systems and overload protection. Additionally, these belts are manufactured with eco-friendly materials, promoting sustainability and reducing the carbon footprint.Section 6: Customer-Centric Approach[Company Name] places great emphasis on understanding customer needs and tailoring their solutions accordingly. Their team of experts works closely with clients to devise customized conveyor belt systems that align with specific requirements and operational goals. This customer-centric approach ensures maximum satisfaction and seamless integration into existing infrastructure.Section 7: Integration of Advanced Technology[Company Name] harnesses the power of advanced technology to enhance the functionality and performance of their conveyor belts. This includes the use of automation, IoT (Internet of Things), and artificial intelligence to enable real-time monitoring, predictive maintenance, and data-driven decision-making. These technological advancements further improve productivity while minimizing downtime and operational costs.Section 8: Global Reach and Collaborative PartnershipsWith a global presence, [Company Name] has successfully established collaborative partnerships with industry leaders to stay at the forefront of technology and innovation. These partnerships ensure constant improvement and the ability to provide comprehensive solutions tailored to specific market demands.Section 9: Future Prospects and InnovationConstantly pushing the boundaries of what is possible, [Company Name] continues to invest in research and development to steer the conveyor belt industry towards a more efficient and sustainable future. Their commitment to innovation ensures that industries worldwide can rely on their expertise to increase productivity and stay ahead in an ever-evolving market.Conclusion:The introduction of [Company Name]'s new line of scrapers conveyor belts promises to transform material handling processes in industries across the globe. With their focus on efficiency, durability, versatility, and customer satisfaction, [Company Name] confirms its position as a leader in the conveyor belt industry. These revolutionary belts have the potential to redefine workplace productivity and set new benchmarks for safety and sustainability.

Efficient and Reliable Roller Conveyor Systems: A Game Changer in Material Handling

Nose Roller Conveyor Improving Efficiency and Precision in Material HandlingIn today's modern manufacturing and warehouse facilities, the need for efficient and precise material handling is crucial for maintaining productivity and meeting customer demands. Businesses are constantly seeking innovative solutions to streamline their processes and improve operating efficiency. This is where the Nose Roller Conveyor, offered by {} comes into play.The Nose Roller Conveyor is a cutting-edge material handling solution that has been developed to meet the growing demands of the industry. The conveyor system is designed to transport a wide variety of products and materials, providing a smooth and reliable movement from one point to another within a facility. With its unique nose roller design, the conveyor can accommodate both flat-bottomed and irregularly shaped items, making it a versatile solution for diverse material handling needs.One of the key features of the Nose Roller Conveyor is its ability to ensure precise alignment and orientation of products during transportation. This is essential for maintaining the integrity of delicate or sensitive items, as well as for optimizing the packing and shipping processes. By minimizing the risk of misalignment or product damage, the conveyor system helps businesses improve their overall operational efficiency and reduce costly errors.In addition to its precision and versatility, the Nose Roller Conveyor is also known for its durability and low maintenance requirements. Constructed from high-quality materials and engineered to withstand the rigors of industrial environments, the conveyor system is designed to deliver long-lasting performance with minimal downtime. This not only helps businesses save on maintenance and repair costs but also ensures continuous and reliable operation for increased productivity.Furthermore, the Nose Roller Conveyor is designed with flexibility in mind, allowing businesses to customize the system to meet their specific requirements. Whether it's integrating additional features, adjusting the conveyor speed, or modifying the layout to fit within the existing facility, the system can be tailored to suit the unique needs of different industries and applications. This kind of adaptability makes the Nose Roller Conveyor an ideal solution for businesses looking to enhance their material handling capabilities.With the rise of Industry 4.0 and the increasing adoption of automation and smart technologies, the Nose Roller Conveyor is also compatible with advanced control systems and software. This enables businesses to incorporate the conveyor system into their overall digital transformation strategy, leveraging real-time data and analytics to optimize workflows and drive continuous improvement in their material handling processes.As {} continues to make advancements in material handling technology, the Nose Roller Conveyor stands as a testament to their commitment to innovation and customer-centric solutions. With a proven track record of delivering reliable and high-performance conveyor systems to a wide range of industries, the company has established itself as a trusted partner for businesses seeking to elevate their operational efficiency and competitiveness.In conclusion, the Nose Roller Conveyor represents a significant advancement in material handling technology, offering businesses a powerful tool to enhance their productivity and accuracy. With its precision, versatility, durability, and adaptability, the conveyor system is poised to play a pivotal role in shaping the future of material handling in the manufacturing and logistics sectors. As businesses continue to invest in modernizing their operations, solutions like the Nose Roller Conveyor will undoubtedly be at the forefront of driving efficiency and innovation in the industry.