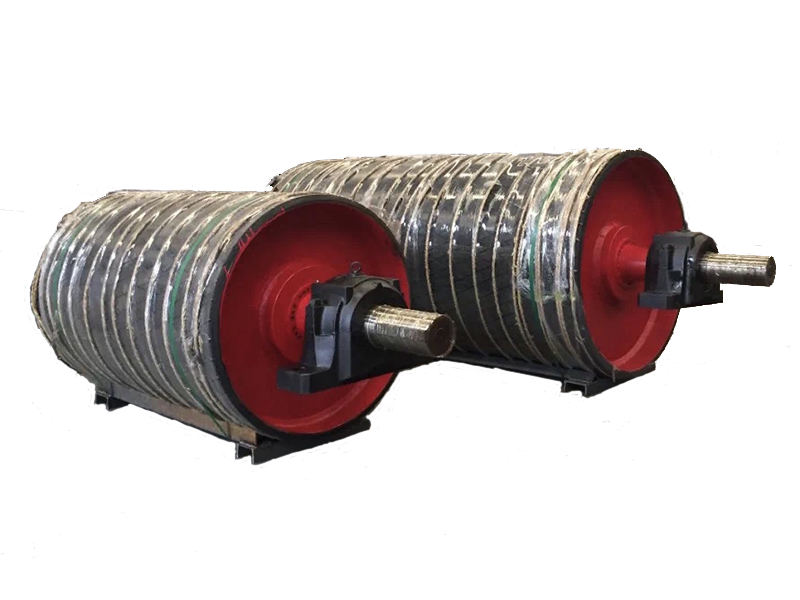

Ultimate Guide to Conveyor Sprocket Design for Smooth Material Handling

By:Admin

When it comes to the design of conveyor sprockets, it is important to consider factors such as the type of material being conveyed, the speed of the conveyor, and the overall load capacity of the system. Proper sprocket design can help to ensure smooth and efficient operation, while also reducing wear and tear on other conveyor components.

This is where the innovative design and engineering expertise of {} come in. With a strong reputation for delivering high-quality conveyor solutions, {} has established itself as a leader in the industry. The company's extensive experience in conveyor system design and manufacturing makes them a go-to choice for businesses in a wide range of industries, including mining, agriculture, and manufacturing.

{} offers a wide range of conveyor sprockets that are designed to meet the specific requirements of each customer. Whether it's a standard sprocket design or a custom solution, {} has the capability to deliver reliable and efficient conveyor components that keep operations running smoothly.

One of the key factors that sets {} apart from its competitors is its commitment to innovation and continuous improvement. The company's team of engineers and designers are constantly looking for ways to enhance the performance and reliability of their conveyor sprockets, ensuring that they meet the evolving needs of their customers.

In addition to their dedication to product innovation, {} also places a strong emphasis on quality and customer satisfaction. All of their conveyor sprockets undergo rigorous testing and quality assurance processes to ensure that they meet the highest standards of performance and durability. This focus on quality has helped {} to build a solid reputation for delivering products that exceed customer expectations.

Furthermore, {} takes pride in providing exceptional customer service and support. Their team of experts is available to assist customers with selecting the right conveyor sprocket for their specific application, as well as provide technical guidance and support throughout the entire process, from design to installation.

With a solid track record of delivering top-quality conveyor solutions, {} continues to be a trusted partner for businesses seeking reliable and efficient conveyor sprocket designs. Their commitment to innovation, quality, and customer satisfaction sets them apart as a leading provider of conveyor system components.

In conclusion, the design of conveyor sprockets plays a crucial role in the overall performance and efficiency of a conveyor system. With the expertise and dedication of companies like {}, businesses can be confident in the reliability and quality of their conveyor sprocket designs, knowing that they are backed by a trusted industry leader.

Company News & Blog

Experts provide tips on how to choose the ideal bucket for your payloader

Payloader Bucket Optimizes Material Handling Capabilities for Construction and Mining IndustriesAs technology continues to advance, so does the machinery and equipment utilized in various industries. Today, advanced machines have been developed to aid in handling materials, specifically, heavy materials, such as gravel, dirt, sand, and rock. The payloader bucket, an attachment piece for heavy machinery, is among the most widely used tools for material handling in construction and mining industries.Payloader buckets, also known as front-end loaders or wheel loaders, are typically used on construction sites to move materials from one place to another. The bucket itself is attached to the front of the loader, and it is used to scoop up materials. Once the material is captured by the bucket, the loader can then transport it to the desired location. A payloader bucket functions as both a shovel and a bulldozer, with its design made to transport large amounts of material quickly and efficiently.In line with the need to provide top-of-the-line payloader buckets, the introduction of (company name) has been a game-changer in the industry. They are dedicated to producing high-quality payloader buckets that are powerful, efficient, and user-friendly in design. Their range of payloader buckets combines the latest technology and innovation to deliver advanced solutions in material handling. The company’s payloader buckets are made from high-quality materials, ensuring durability and longevity. They are designed to be user-friendly, with optimal visibility from inside the cab of the loader, making it easier for operators to maneuver the bucket and increase productivity. Each bucket is customized to meet the specific needs of customers, with options for different sizes, shapes, and capacities depending on the purpose.While payloader buckets may seem like a relatively simple tool, the technology behind them has continued to improve in recent years. One of the key features of (company name) payloader buckets is the implementation of advanced hydraulic systems, resulting in outstanding power and efficiency when handling materials. The hydraulic system enhances the lifting and lowering capability of the bucket, thereby improving overall efficiency, reducing idle time, and increasing productivity. Additionally, the hydraulic system enables fast and smooth movement of the bucket, making it easier for the operator to handle the materials.In terms of safety, (company name) payloader buckets have been designed with operators in mind. The company’s buckets come with added safety features to ensure that the operator is protected while using the tool. The company emphasizes safety in the design of their payloader buckets, as the industry is filled with potential hazards that could put the life of an operator in danger. These safety features include a locking bucket pin, which secures the bucket in place when not in use, and a high visibility striped sticker set, designed to draw attention to the loader and reduce the risk of collision or accidents.The need for efficiency in the handling of large volumes of materials has made (company name) payloader buckets the preferred choice for construction and mining companies. With their high durability, increased lifting and lowering power, safety features, and advanced hydraulic systems, the payloader buckets produced by the company enable companies to increase the overall efficiency of their operations.In addition to the production of high-quality payloader buckets, (company name) provides an excellent after-sales service system that caters to the support and maintenance needs of customers. The company’s technical support team is available around the clock to provide assistance to customers. This level of support helps to ensure that the payloader buckets perform optimally for extended periods, thereby increasing the lifespan of the tool.In conclusion, the payloader bucket is an important tool used in construction and mining industries to transport large volumes of materials. (company name) has established itself as a leading manufacturer of payloader buckets by developing advanced and durable products that are designed to increase efficiency, while ensuring operator safety. Their range of products combines the latest technology and innovation, making them the go-to choice for construction and mining companies looking for high-quality payloader buckets. With the company's commitment to customer satisfaction through excellent after-sales service, it is clear that (company name) is poised to remain at the top of the material handling industry for years to come.

How a Conveyor Roller Benefits Material Handling Processes

Chain Conveyor Roller: A Durable and Reliable Industrial Solution for Material HandlingAs the world progresses, industries continue to evolve, and so does the need for advanced and efficient technology to aid material handling. Whether it be in mining, manufacturing, or agriculture, there is a constant demand for reliable machinery to transport heavy loads. This is where the Chain Conveyor Roller comes into play, providing industrial solutions to cater to the various material handling requirements of diverse sectors of the economy. Chain Conveyor Rollers are cylindrical components that incorporate bearings to reduce friction and optimize the movement of heavy materials. Realizing the need for superior quality rollers that can withstand the harsh conditions of industrial environments, a company (need remove brand name) developed and introduced their line of Chain Conveyor Rollers. These rollers have a durable build, making them ideal for use in severe weather conditions, heavy-duty industrial loads, and even underground mining.Some of the features of Chain Conveyor Rollers that set them apart from other material handling solutions include:1. High performing bearings that minimize friction and reduce energy consumption2. Robust design, ensuring a long and trouble-free service life3. Easy installation and maintenance, making them a cost-effective solution for industrial clients4. Resistance to extreme temperatures and harsh environments 5. Ability to transport large, heavy loads with ease Furthermore, Chain Conveyor Rollers can be customized to meet the exact requirements of different industries. Some of the customization options include:1. Fabric materials - such as nylon, plastic, or steel, that suit various weight and resistance specifications2. Coatings - protective finishes that increase the rollers' wear and tear resistance3. Roller length, width, and diameter - that can be customized to specific client requirements4. Brackets - designed to work with different roller sizes and conveyor load ratingsChain Conveyor Rollers have a wide range of applications across various industrial sectors. In the manufacturing industry, the rollers are used in the production of various goods. The agricultural sector utilizes them for transporting crops and livestock. In the mining sector, Chain Conveyor Rollers provide a reliable solution for material transportation in underground and surface mining operations.As a testament to their durability and reliability, various industrial clients have already incorporated Chain Conveyor Rollers into their operations. For instance, a global cement manufacturing company used these rollers for their conveyor systems and reported significant efficiency improvements. In another steel manufacturing company, custom-made Chain Conveyor Rollers reduced energy consumption and maintenance needs, consequently widening the profit margin.In light of the current economic climate, businesses emphasize a value-over-cost approach in their operations. Fortunately, Chain Conveyor Rollers offer clients value and performance without risking production or safety. The rollers offer unmatched durability and advanced designs that have gained widespread adoption in material production and transportation. In conclusion, the industrial sector is ever-changing, with the need for robust machinery that can easily handle heavy materials and endure harsh environments always present. Chain Conveyor Rollers incorporate innovation and excellence, delivering reliability, cost-effectiveness, and high-performance material handling solutions. Therefore, deploying Chain Conveyor Rollers in your operations could be the key differentiator that sets your company apart from competitors.

Incline Conveyor: All You Need to Know About Z Technology

Z Incline Conveyor, a leading manufacturer of innovative material handling solutions, has recently introduced a revolutionary new product that is set to transform the industry. The company, known for its commitment to quality and innovation, has been a driving force in the material handling industry for over 30 years. Their latest development, the Incline Conveyor, is a game changer that promises to streamline the transportation of materials and improve efficiency in a wide range of applications.The Incline Conveyor is designed to elevate materials at a steep angle, allowing for seamless transportation between different levels of a facility. This versatile piece of equipment is capable of handling a wide variety of materials, including bulk solids, small parts, and irregularly shaped items. Its robust construction and high-quality components make it a reliable and durable solution for even the most demanding material handling environments.One of the key features of the Incline Conveyor is its modular design, which allows for easy customization to meet the specific needs of each customer. Whether it's a food processing facility, a manufacturing plant, or a distribution center, the conveyor can be tailored to fit the unique requirements of any application. This flexibility makes it a valuable addition to any material handling operation, offering improved efficiency and productivity.In addition to its customizable design, the Incline Conveyor also boasts a range of advanced features that set it apart from traditional material handling equipment. These include a user-friendly interface, advanced safety systems, and energy-efficient operation. The conveyor is also designed to be easy to maintain, reducing downtime and lowering overall operating costs."With the introduction of the Incline Conveyor, we are proud to continue our tradition of innovation in the material handling industry," said the company's CEO. "We believe that this product represents a significant advancement in the way materials are transported within a facility. Its versatility, reliability, and efficiency make it an ideal solution for a wide range of industries."The Incline Conveyor has already garnered significant interest from a variety of industries, with early adopters praising its performance and reliability. This positive feedback is a testament to the company's commitment to providing cutting-edge solutions that address the evolving needs of the material handling industry.As the industry continues to evolve, the Incline Conveyor is poised to play a crucial role in improving efficiency and productivity for material handling operations around the world. Its innovative design and advanced features make it a valuable addition to any facility, offering a competitive edge in an increasingly demanding market.With a track record of success and a strong commitment to innovation, Z Incline Conveyor is well positioned to lead the way in the material handling industry. The introduction of the Incline Conveyor is just the latest example of the company's dedication to providing forward-thinking solutions that deliver real results for its customers.As the industry continues to evolve, Z Incline Conveyor remains at the forefront, driving innovation and setting new standards for efficiency and reliability in material handling. The Incline Conveyor is a testament to the company's ongoing commitment to excellence, and it is sure to make a significant impact on the industry for years to come.

Efficient and Reliable Unloading Belt Solutions for Your Business Needs

[Company Name] Unveils Advanced Unloading Belt for Increased Efficiency[City, Date] – [Company Name], a leader in manufacturing and technology solutions, has recently announced the launch of its new and improved Unloading Belt. The unloading belt is designed to streamline the process of unloading materials and products, making it more efficient and seamless for businesses across various industries.The Unloading Belt is equipped with advanced technology and features that make it stand out from other similar products in the market. With a focus on efficiency and safety, the Unloading Belt is designed to meet the demands of modern businesses and help them improve their operational processes.One of the key features of the Unloading Belt is its high capacity and speed, allowing for the quick and efficient unloading of materials and products. This is particularly beneficial for companies dealing with large volumes of materials on a regular basis, as it can significantly reduce the time and labor required for unloading processes.In addition, the Unloading Belt is equipped with advanced safety features to ensure the protection of workers and the materials being unloaded. This includes automated monitoring systems and alarms to alert operators of any potential issues or hazards, as well as built-in safety mechanisms to prevent accidents and injuries.Moreover, the Unloading Belt is designed to be highly customizable, allowing businesses to tailor it to their specific needs and requirements. From adjustable speed and capacity settings to various options for material handling, the Unloading Belt can be adapted to suit the unique demands of different industries and applications.Furthermore, the Unloading Belt is built to be durable and long-lasting, requiring minimal maintenance and ensuring reliable performance over an extended period of time. This makes it a cost-effective solution for businesses looking to improve their unloading processes without having to constantly invest in repairs and replacements.[Company Name] has a long-standing reputation for delivering innovative and high-quality products to its customers. With a focus on continuous research and development, the company is dedicated to pushing the boundaries of technology and engineering to create solutions that address the evolving needs of businesses in various industries.The Unloading Belt is the latest addition to [Company Name]'s extensive product line, which includes a wide range of solutions for material handling, automation, and industrial processes. By leveraging its expertise and experience in these areas, the company is able to offer comprehensive and reliable solutions that help businesses improve their productivity and efficiency.In addition to its commitment to product innovation, [Company Name] is also known for its excellent customer service and support. With a team of highly skilled and knowledgeable professionals, the company offers comprehensive assistance to its customers, from initial product inquiries to installation and maintenance services.The launch of the Unloading Belt reflects [Company Name]'s ongoing dedication to providing valuable and impactful solutions to its customers. By introducing a product that addresses the specific challenges and needs of businesses in material handling and unloading processes, the company is poised to make a significant impact on the industry.As businesses continue to seek ways to optimize their operations and improve their efficiency, the Unloading Belt by [Company Name] has the potential to become a game-changer. With its advanced technology, customizable features, and focus on safety and reliability, it is set to deliver tangible benefits to businesses across various sectors.In conclusion, the launch of the Unloading Belt by [Company Name] represents a significant milestone in the company's commitment to innovation and excellence. With its advanced features and capabilities, the Unloading Belt is poised to become a valued asset for businesses seeking to streamline their unloading processes and enhance their overall operations.

The Latest Innovation in Conveyor Systems: Nose Roller Conveyors

[Company Name] Introduces Innovative Nose Roller Conveyor to Optimize Efficiency and Productivity in Material Handling Industry[date][City, State] - [Company Name], a global leader in material handling solutions, is proud to announce the launch of its latest product, the Nose Roller Conveyor. This innovative conveyor system is designed to revolutionize the way businesses handle material, offering increased efficiency and productivity in a demanding and fast-paced industry.The Nose Roller Conveyor is specifically engineered to enhance the movement of cartons and boxes in warehouses, distribution centers, and manufacturing facilities. By combining advanced technology and superior design, [Company Name] has developed a solution that streamlines material handling processes and minimizes downtime.Featuring a unique nose roller design, this conveyor system enables smooth and consistent transferring of products. The specialized rollers ensure easy and accurate package handling, preventing jams and reducing the risk of damages. With its high load capacity and unmatched reliability, the Nose Roller Conveyor can handle a wide range of materials and help businesses maintain their competitive edge.One of the key advantages of the Nose Roller Conveyor is its versatility. This system can be easily integrated into existing material handling setups, minimizing the need for costly modifications or equipment replacements. Its flexible design allows for customization based on individual business requirements, ensuring a seamless fit within different operational environments.[Company Name] is renowned for its commitment to innovation and customer satisfaction. The development of the Nose Roller Conveyor aligns with the company's mission to provide cutting-edge solutions that optimize efficiency and enhance operational performance. With a dedicated team of engineers and industry professionals, [Company Name] has focused on refining existing technologies and introducing new concepts to meet the evolving demands of the material handling industry."We are thrilled to introduce the Nose Roller Conveyor to the market. We understand the challenges faced by businesses in the material handling industry and believe that this new system will significantly improve their workflows," said [Company Name]'s CEO, [Name]. "Our goal is to empower our customers by offering reliable, efficient, and innovative solutions that enhance their productivity and success."With its global presence, [Company Name] is well-equipped to meet the international demand for quality material handling solutions. The Nose Roller Conveyor is built to withstand even the most rigorous conditions, making it suitable for businesses of all sizes and industries. From e-commerce giants to manufacturing powerhouses, companies can benefit from the cutting-edge technology integrated into this conveyor system.The introduction of the Nose Roller Conveyor underscores [Company Name]'s commitment to sustainability and environmental responsibility. By providing efficient material handling solutions, businesses can minimize their carbon footprint, reduce waste, and optimize their use of resources. This aligns with [Company Name]'s vision of a more sustainable future, where companies can achieve growth while prioritizing environmental stewardship.In conclusion, [Company Name] continues to revolutionize the material handling industry with the launch of its Nose Roller Conveyor. This versatile and innovative system offers businesses increased efficiency, productivity, and flexibility while reducing operational costs. As a leader in the field, [Company Name] is dedicated to providing world-class solutions that empower businesses to thrive amidst the challenges of the modern marketplace.For more information about the Nose Roller Conveyor and other cutting-edge material handling solutions, please visit [company website] or contact [company representative] at [contact information].###About [Company Name]:[Company Name] is a global leader in providing innovative material handling solutions. With an extensive range of products and services, the company is dedicated to helping businesses optimize their operational performance, enhance productivity, and achieve sustainable growth. By combining advanced technology, superior engineering, and exceptional customer service, [Company Name] continues to set new standards in the material handling industry.

Highly Efficient and Versatile Conveyor Belt System for Material Handling Applications

In today's fast-paced and ever-growing industrial landscape, the efficient movement of products and materials is more important than ever. That's why the introduction of the Hugger Belt Conveyor by {} is a game-changer for the industry. With its innovative design and advanced technology, this conveyor system is set to revolutionize the way products are transported and handled.The Hugger Belt Conveyor is a cutting-edge system that utilizes a unique method of conveying products. Unlike traditional belt conveyors, this system features a series of individual belt segments that are closely spaced together. This design allows the conveyor to "hug" the products as they move along the belt, providing a gentle and secure way of transporting even the most delicate items. The close spacing of the belt segments also prevents small items from getting caught or lost in the conveyor system, ensuring a smooth and efficient operation.One of the key features of the Hugger Belt Conveyor is its versatility. This system is capable of handling a wide range of products, from small and lightweight items to larger and heavier loads. The conveyor can be easily adjusted to accommodate different product sizes and shapes, making it an ideal solution for a variety of industries, including food and beverage, pharmaceuticals, and manufacturing.In addition to its versatility, the Hugger Belt Conveyor is also designed with efficiency and productivity in mind. The system is equipped with advanced automation technology, including sensors and controls that allow for precise tracking and positioning of products. This not only ensures smooth and consistent movement along the conveyor, but also minimizes the risk of product damage or loss. Furthermore, the conveyor is designed to be low-maintenance, reducing downtime and increasing overall productivity.The Hugger Belt Conveyor is also designed with safety in mind. With its close belt spacing and gentle product handling, this system minimizes the risk of injuries and accidents in the workplace. Additionally, the conveyor is equipped with safety features such as emergency stop buttons and protective guards, further ensuring the well-being of workers and the integrity of the products being transported.{} is a leading provider of innovative conveyor systems and material handling solutions. With a strong focus on quality, reliability, and customer satisfaction, the company has established itself as a trusted partner for businesses across a wide range of industries. The introduction of the Hugger Belt Conveyor is a testament to the company's commitment to innovation and excellence, providing its customers with the latest in conveyor technology.The launch of the Hugger Belt Conveyor is a major milestone for both {} and the industry as a whole. With its unique design, advanced technology, and focus on efficiency and safety, this system is set to revolutionize the way products are transported and handled. As businesses continue to strive for greater productivity and performance, the Hugger Belt Conveyor provides a solution that is not only reliable and versatile, but also tailored to meet the evolving needs of modern industries. With {} leading the way, the future of conveyor systems looks brighter than ever.

Plastic Screw Auger: High-Performance Solution for Various Industries

Title: Innovative Plastic Screw Auger Revolutionizes Manufacturing ProcessIntroduction:In today's rapidly evolving manufacturing landscape, finding efficient and sustainable solutions is crucial. Plastic Screw Auger, developed by (Company Name), has emerged as a game-changing technology that offers numerous advantages over traditional metal screw augers. With its unique design and exceptional performance, this innovative solution is reshaping the manufacturing industry, facilitating improved efficiency, reduced costs, and enhanced sustainability.1. The Need for Innovation in Manufacturing:The global manufacturing sector has witnessed a steady shift towards sustainability and efficiency in recent years. Companies are constantly seeking innovative solutions that minimize environmental impact while maximizing productivity. This growing demand for eco-friendly technologies paves the way for (Company Name)'s Plastic Screw Auger.2. Introducing the Plastic Screw Auger:(Company Name)'s Plastic Screw Auger demonstrates their commitment to reimagining traditional manufacturing components. The auger is made from high-quality, durable plastic materials, which offer several advantages over conventional metal screw augers. It is designed to facilitate a broad range of manufacturing processes, such as material conveying, mixing, and extrusion.3. Unparalleled Performance:The Plastic Screw Auger boasts several features that set it apart from its metal counterparts. Firstly, its lightweight design enables easier handling and reduces fatigue during operation. This aspect significantly enhances productivity as the auger can be quickly and effortlessly maneuvered.Moreover, the plastic material used in its construction is highly resistant to corrosion, ensuring longevity even when exposed to harsh chemicals and extreme conditions. This durability translates into reduced maintenance costs and increased operational efficiency for manufacturers.4. Enhanced Efficiency:The incredible precision and consistency exhibited by the Plastic Screw Auger make it an ideal solution for intricate manufacturing processes that require accurate material mixing, blending, or feeding. By ensuring a consistent flow of materials, it eliminates the risk of costly errors and product defects.Additionally, the plastic material's low friction coefficient allows for improved flow rates, reducing downtime caused by clogging. This advantage significantly enhances productivity by maintaining a steady production pace.5. Sustainability at the Core:The Plastic Screw Auger aligns with the growing emphasis on sustainability in the manufacturing industry. Its construction using high-quality plastic materials reduces dependency on metal, thereby minimizing environmental impact. Unlike traditional metal augers, it does not require extensive mining and processing of resources, resulting in a smaller carbon footprint.Furthermore, the auger's lighter weight reduces energy consumption during operation, contributing to overall energy savings. Manufacturers can now embrace sustainable practices without compromising on performance or efficiency.6. Wide Range of Applications:The adaptability of the Plastic Screw Auger allows it to be employed across various manufacturing sectors. From pharmaceutical and food processing to automotive and packaging industries, this innovative technology proves its versatility. Its ability to handle diverse materials, such as powders, granules, and liquids, makes it an invaluable asset for manufacturers seeking to streamline their processes.7. Future Possibilities:Driven by a strong commitment to continuous improvement, (Company Name) is actively exploring further advancements in plastic material engineering. Research and development efforts aim to expand the applications of the Plastic Screw Auger, making it suitable for even more intricate manufacturing procedures.Conclusion:In an era where sustainability and efficiency reign, the Plastic Screw Auger developed by (Company Name) presents an innovative solution to revolutionize manufacturing processes. With its cutting-edge design, enhanced efficiency, and reduced environmental impact, this game-changing technology is poised to shape the future of the manufacturing industry. As (Company Name) continues to push boundaries, the possibilities for this innovative solution are endless, ensuring a more sustainable and productive manufacturing landscape.

High-Quality Conveyor Belt Spare Parts for Improved Efficiency

Conveyor Belt Spare Parts – The Key to Keeping Operations Running SmoothlyIn the fast-paced world of manufacturing and distribution, having a reliable conveyor system is crucial for keeping operations running smoothly. Whether it's moving packages through a distribution center or transporting materials in a production facility, conveyor belts play a vital role in the efficiency and productivity of any operation. However, like any mechanical system, conveyor belts are prone to wear and tear, and having access to high-quality spare parts is essential for minimizing downtime and maintaining peak performance.That's where {Company Name} comes in. With over 20 years of experience in the industry, {Company Name} has established itself as a leading supplier of conveyor belt spare parts. From rollers and pulleys to bearings and belts, {Company Name} offers a comprehensive range of spare parts that are designed to meet the needs of a wide variety of conveyor systems.One of the key factors that sets {Company Name} apart from its competitors is the quality of its spare parts. All of the parts offered by {Company Name} are manufactured to the highest standards, using premium materials and cutting-edge technology. This ensures that customers can rely on {Company Name} to provide durable, long-lasting spare parts that will keep their conveyor systems running smoothly for years to come.In addition to the quality of its products, {Company Name} also prides itself on its exceptional customer service. The company's team of experienced professionals is dedicated to providing personalized support and guidance to help customers find the right spare parts for their specific needs. Whether it's identifying the right part for a particular conveyor system or providing technical assistance for installation and maintenance, {Company Name} is committed to ensuring that its customers have a seamless experience from start to finish.Furthermore, {Company Name} understands the importance of quick and efficient delivery. With a well-established network of distribution centers, the company is able to provide fast and reliable shipping to customers worldwide. This means that even in the event of a breakdown or emergency, customers can count on {Company Name} to deliver the spare parts they need in a timely manner, helping to minimize downtime and keep operations running smoothly.In today's fast-paced and demanding business environment, having a reliable and efficient conveyor system is more important than ever. With {Company Name} as a trusted partner, customers can have peace of mind knowing that they have access to top-quality spare parts, backed by exceptional customer service and quick delivery. Whether it's replacing a worn-out roller or upgrading to a more durable belt, {Company Name} is the go-to source for all conveyor belt spare parts needs.The company's commitment to quality, customer service, and efficiency has earned it a reputation as a trusted and reliable supplier in the industry. With a wide range of spare parts that are designed to meet the needs of various conveyor systems, {Company Name} is the one-stop shop for all conveyor belt spare parts needs. So, if you're looking to keep your operations running smoothly and minimize downtime, look no further than {Company Name} for all your conveyor belt spare parts needs.

Efficient Sliding Belt Conveyor: Advancements and Key Features Explored

The Sliding Belt Conveyor, a highly efficient material handling system, is making waves in the industry. With its unique design and advanced features, businesses can now speed up their processes, streamline operations, and ultimately increase profitability.The Sliding Belt Conveyor is composed of a sliding belt that moves along a fixed track to transport materials from one end to another. It is designed to minimize manual intervention and increase productivity, allowing businesses to focus on other critical aspects of their operations.One of the primary advantages of the Sliding Belt Conveyor is its flexibility. It can be customized to cater to the specific needs of the business, making it ideal for factories, warehouses, and distribution centers. The design and configuration of the conveyor can be adjusted to accommodate different types of materials, including heavy loads and irregular shapes.Furthermore, the Sliding Belt Conveyor boasts several advanced features that make it even more efficient. For instance, the conveyor can be equipped with sensors and controls that monitor and regulate its speed, ensuring that the materials are transported at optimal speeds. Additionally, it can be integrated with other machines and equipment, such as sorters and container loaders, to further streamline the material handling process.The Sliding Belt Conveyor is manufactured by a leading company that specializes in designing and producing conveyor systems for various industries. With years of experience and expertise, the company has designed the Sliding Belt Conveyor to meet the highest standards of quality and efficiency.In addition to the Sliding Belt Conveyor, the company offers a range of other conveyor systems, including gravity roll, chain, and belt conveyors. Customers can choose the system that best suits their needs, and the company's team of experts will work with them to customize the system to their specifications.The company's commitment to quality and customer satisfaction sets it apart from its competitors. It has a team of dedicated professionals who are always available to provide technical assistance and offer solutions to any challenges that may arise. Furthermore, the company offers training and support to ensure that customers can maximize the benefits of their systems.The Sliding Belt Conveyor is already making a significant impact in various industries, from manufacturing to logistics. Companies that have adopted the system attest to its efficiency, reliability, and cost-effectiveness, and are experiencing increased productivity and profitability.In conclusion, the Sliding Belt Conveyor is a game-changer in the world of material handling. Its unique design, advanced features, and flexibility make it the ideal system for businesses looking to improve their operations. With the backing of a reliable company that offers quality and customer satisfaction, businesses can rest assured that they are making the right investment by adopting the Sliding Belt Conveyor.

Tail Pulley for Belt Conveyors: A Complete Guide

The {Company Name} has recently announced the development of a new belt conveyor tail pulley, adding to their extensive range of conveyor components. The company has been a leading manufacturer of conveyor systems and components for over 20 years, specializing in providing high-quality and customized solutions for a wide range of industries.The new belt conveyor tail pulley is designed to improve efficiency and reliability in conveyor systems, offering a durable and high-performance solution for the mining, aggregate, and bulk material handling industries. The tail pulley plays a crucial role in the operation of a conveyor system, providing the necessary tension and support for the conveyor belt to function effectively.{Company Name}’s belt conveyor tail pulley is constructed using high-quality materials and advanced manufacturing techniques to ensure maximum durability and performance. The pulley features a heavy-duty design, with a solid steel construction and precision-machined components to withstand the demands of heavy-duty applications. In addition, the pulley is equipped with an efficient bearing system to minimize friction and wear, contributing to the overall reliability and longevity of the conveyor system.The design of the new tail pulley also focuses on ease of installation and maintenance, with features such as a removable end plate and self-cleaning mechanism to facilitate quick and hassle-free maintenance procedures. This is in line with {Company Name}’s commitment to providing practical and user-friendly solutions for their customers, enhancing the overall operational efficiency and productivity of their conveyor systems.Furthermore, the new belt conveyor tail pulley is available in a variety of sizes and configurations to accommodate different conveyor designs and requirements, providing customers with the flexibility to tailor the pulley to their specific applications. This customization capability reflects {Company Name}’s dedication to meeting the unique needs of their customers and delivering solutions that are perfectly suited to their operational challenges.In addition to the new belt conveyor tail pulley, {Company Name} offers a comprehensive range of conveyor components, including idlers, pulleys, and accessories, all designed to meet the highest industry standards for quality and performance. The company’s expertise in conveyor systems is backed by a team of skilled engineers and technicians who are committed to providing expert advice and support to customers, ensuring that they receive the most effective solutions for their material handling requirements.With their extensive experience and technical capabilities, {Company Name} has established a strong reputation for delivering reliable and innovative conveyor solutions to a global customer base. The addition of the new belt conveyor tail pulley further strengthens the company’s position as a trusted partner for businesses in the mining, aggregate, and bulk material handling industries, providing them with the confidence to optimize their conveyor systems for maximum efficiency and productivity.As {Company Name} continues to expand their product offerings and enhance their capabilities, they remain dedicated to upholding their commitment to quality, innovation, and customer satisfaction. The development of the new belt conveyor tail pulley is a testament to the company’s ongoing efforts to provide cutting-edge solutions that address the evolving needs of their customers and the industry as a whole. With a focus on performance, reliability, and customization, {Company Name} is poised to remain a leader in the conveyor systems market for years to come.